Aluminum Face Seal ATCR Fitting, VCR Fitting

To add this product to your quote cart or for CAD file access, please login or create an account.

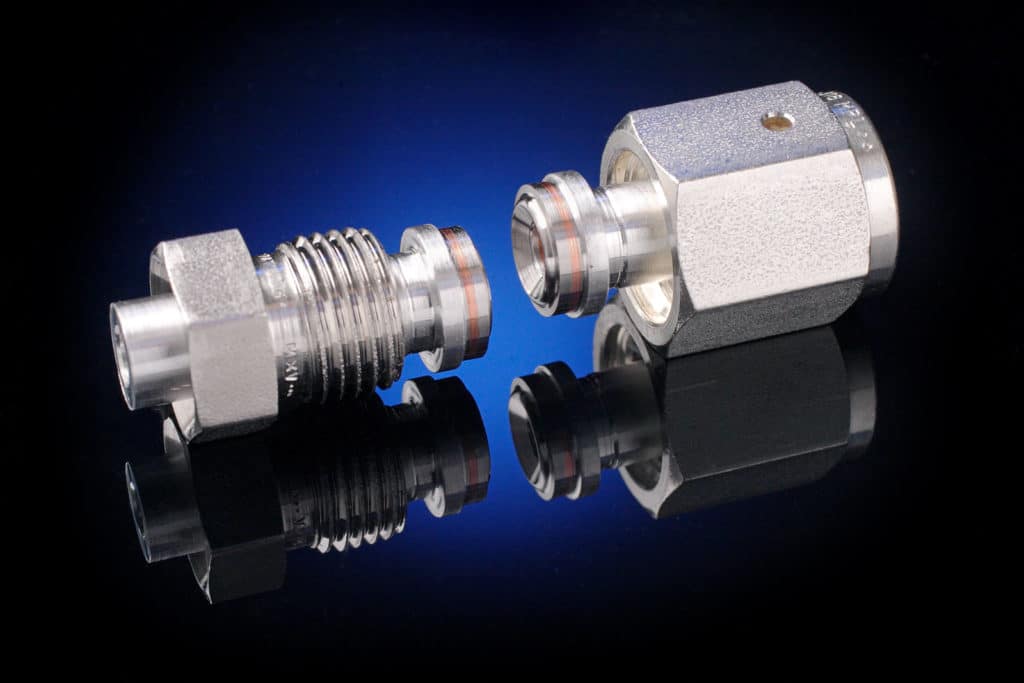

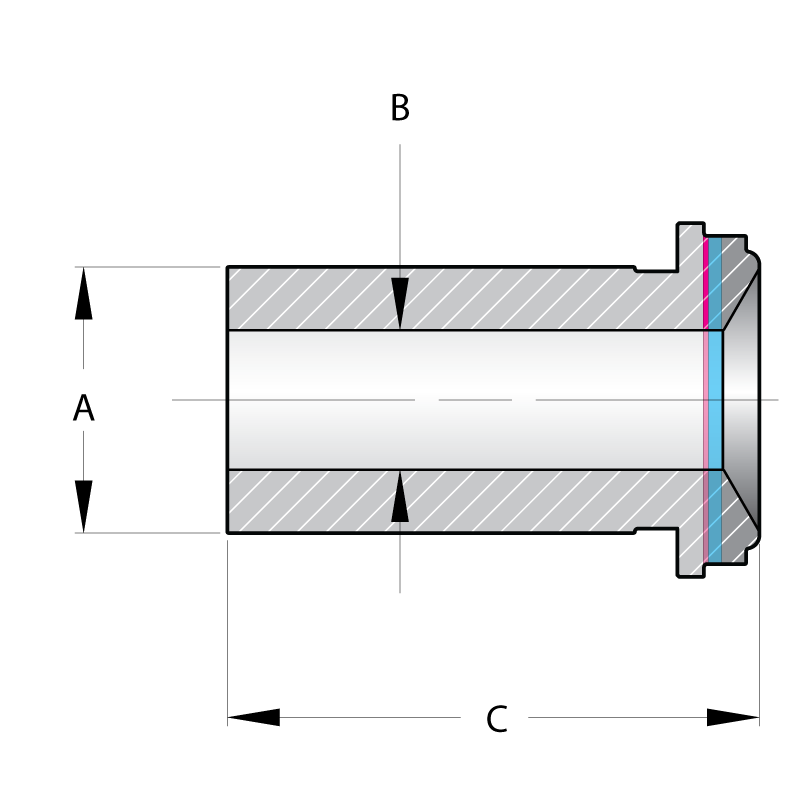

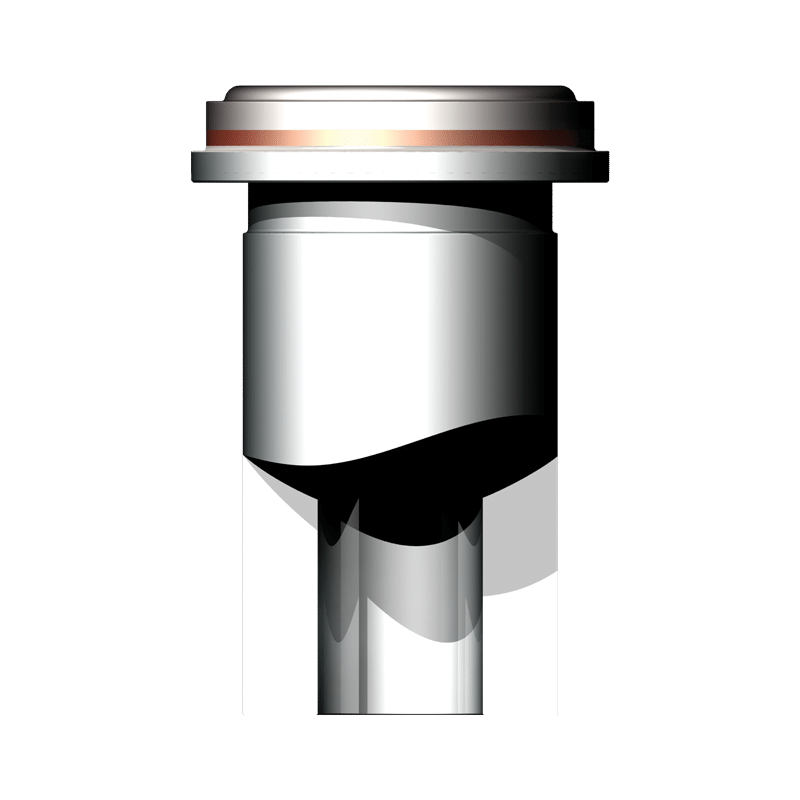

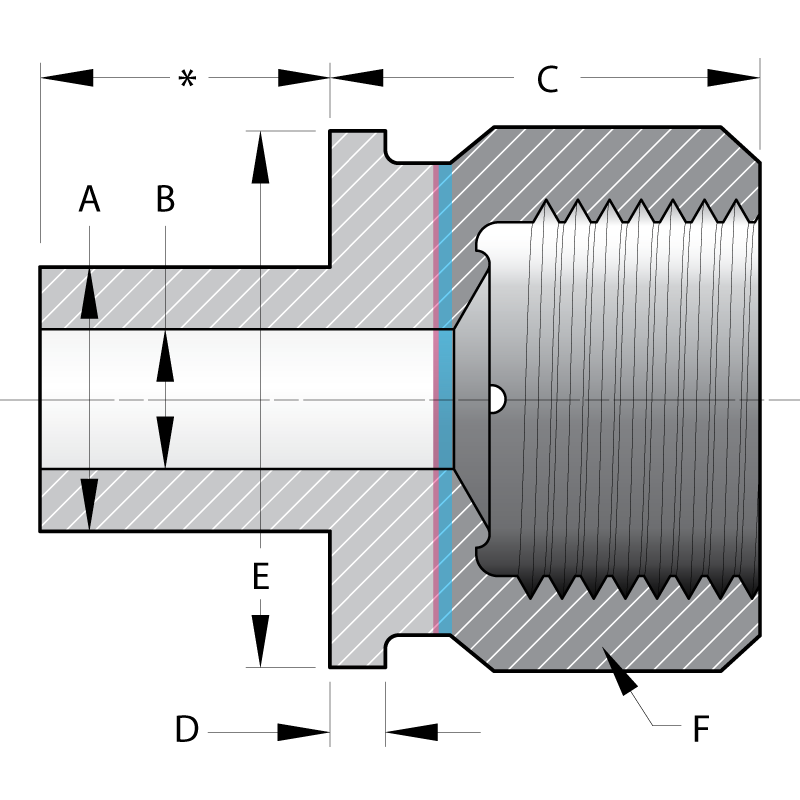

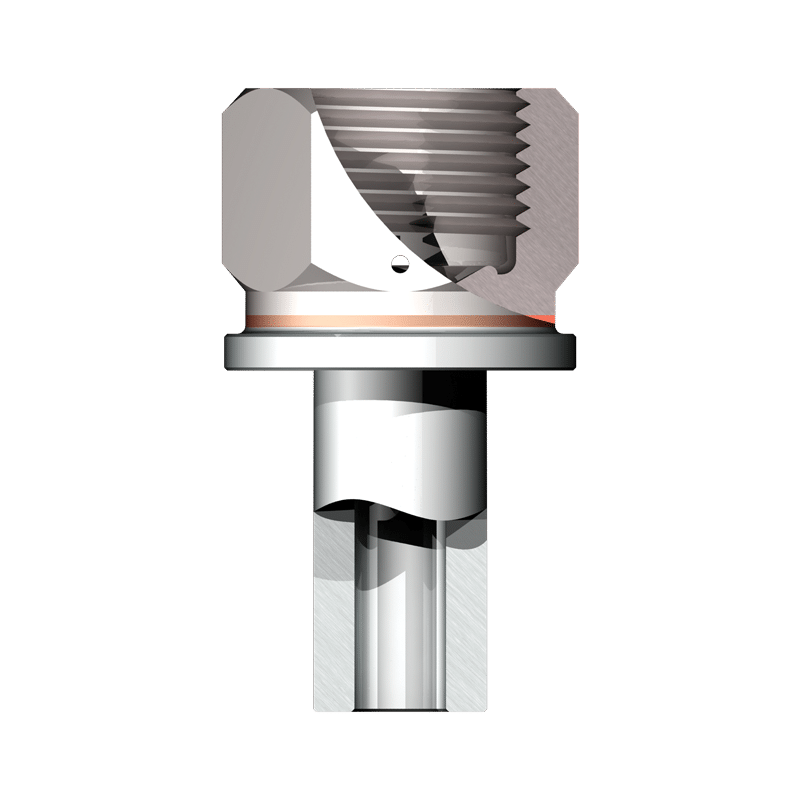

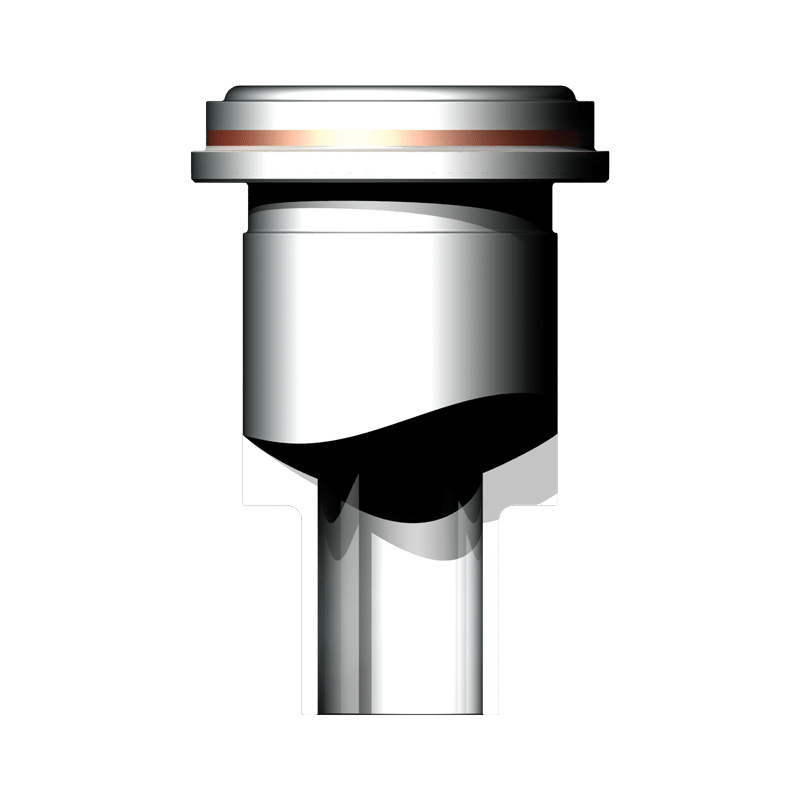

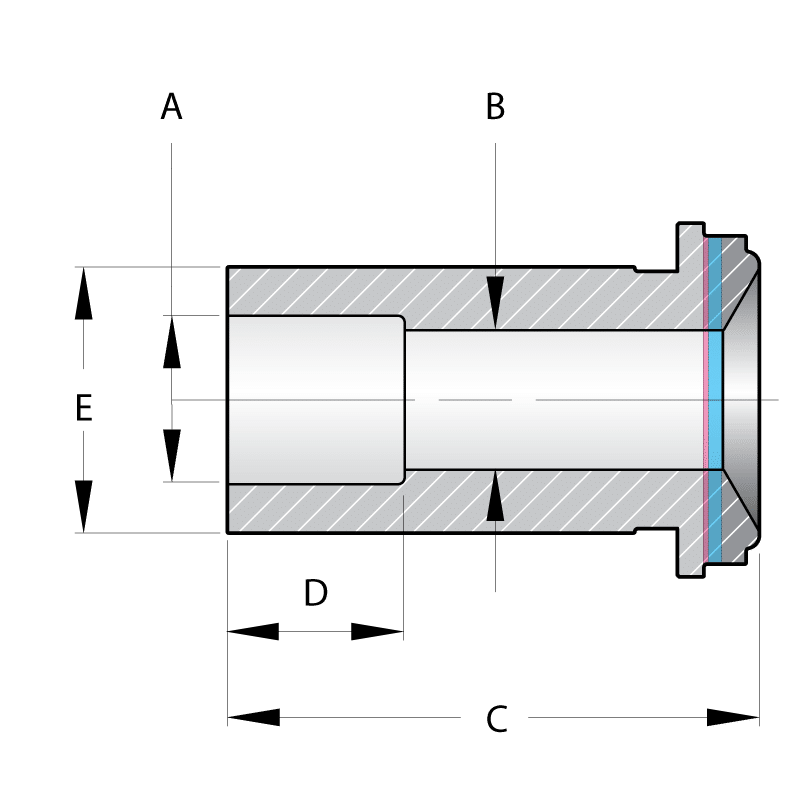

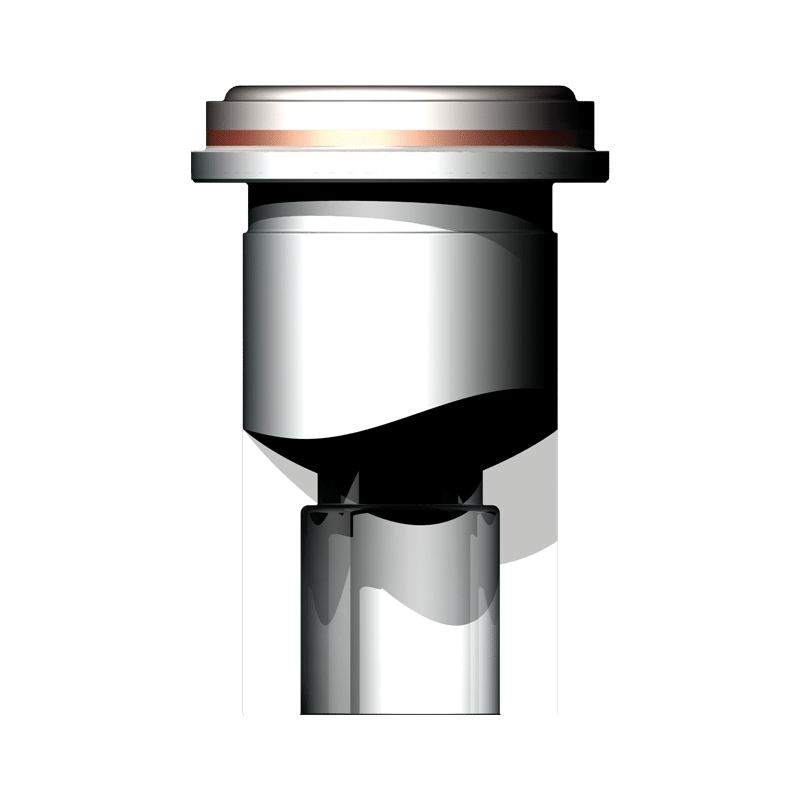

Atlas Socket Weld, Butt Weld, Male Weld, and Chamber Mount ATCR™ face-seal fittings are fitted with a durable stainless steel sealing face that is explosion welded (EXW) to an aluminum body. The bond produced is extremely rugged. All face-seal fittings are helium leak tested for service in UHV environments in excess of 1×10-9 Torr. Atlas ATCR™ fittings enable robust, demountable use of aluminum tubing in cryogenic, physics, and semiconductor applications worldwide. Standard Socket, Butt, Male and Chamber Mount geometries are available in 1/4, 3/8, 1/2, 3/4 and 1 inch tube diameters. Chamber Mount fittings are available in four length configurations suitable for 1/2, 3/4, 1 and 1-1/4 inch chamber wall thicknesses.

Atlas ATCR™ fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings. Unlike these other fittings, however, Atlas ATCR™ fittings are used where high thermal conductivity and high chemical resistance is needed or where any of the advantageous physical properties of aluminum are required.

Atlas bimetallic ATCR™ fittings: the aluminum tube fitting with a stainless steel face-seal that makes UHV aluminum vacuum systems a reality.

Specifications:

Atlas aluminum ATCR™ face-seal fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings.

Materials:

- Body/Weld Interface: Aluminum 6061-T6

- Seal-Face: Stainless Steel 316L, Optional Titanium (commercially pure)

- Rotatable Nut: Stainless Steel 316

Environmental:

- Vacuum: Leak tested to <1 x 10-9 cc/sec of He

Thermal

- Temperature, Peak: 300ºC (During weld-up)

- Temperature, Operational: -200ºC to 250ºC

Mechanical (EXW Interface):

- Tensile: 15,000psi

- Shear: 10,000psi

Applications:

- Cryogenic feed lines

- Aerospace

Diagrams & Variations

Related Content

-

ATCR Fittings Deliver Advanced Functionality

For the most challenging applications in the fields of cryogenics, aerospace, physics, and semiconductors, Atlas ATCR™ fittings produces a robust, demountable use of aluminum tubing. These fittings are fully compatible with Swagelok VCR® and Parker-Hannifin VacuSeal® fittings which makes incorporating Atlas ATCR™ fittings into existing stainless infrastructure uncomplicated. For processes that require high thermal conductivity, … Continued

-

Customer Highlight: Dynavac

Our customers at Dynavac are crucial participants in a compelling project for NASA’s Magnetospheric Multiscale Mission at the Goddard Space Center. The Solar Terrestrial Probes mission will fly four identically instrumented satellites to investigate how the sun and Earth’s magnetic fields transfer energy from one to the other. This transfer, called Magnetic Reconnection, affects space … Continued

-

Aluminum’s Extreme Vacuum Performance

Aluminum’s Extreme Vacuum Performance Any single physical or chemical property of aluminum may be enough reason to select aluminum as a vacuum chamber choice over stainless steel. But when looked at in summary, aluminum overwhelmingly surpasses stainless steel as providing the lowest cost of ownership. Aluminum has seven orders of magnitude less hydrogen than stainless … Continued