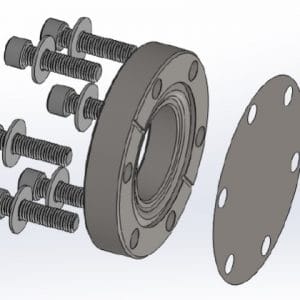

Foil Window Flange

To add this product to your quote cart or for CAD file access, please login or create an account.

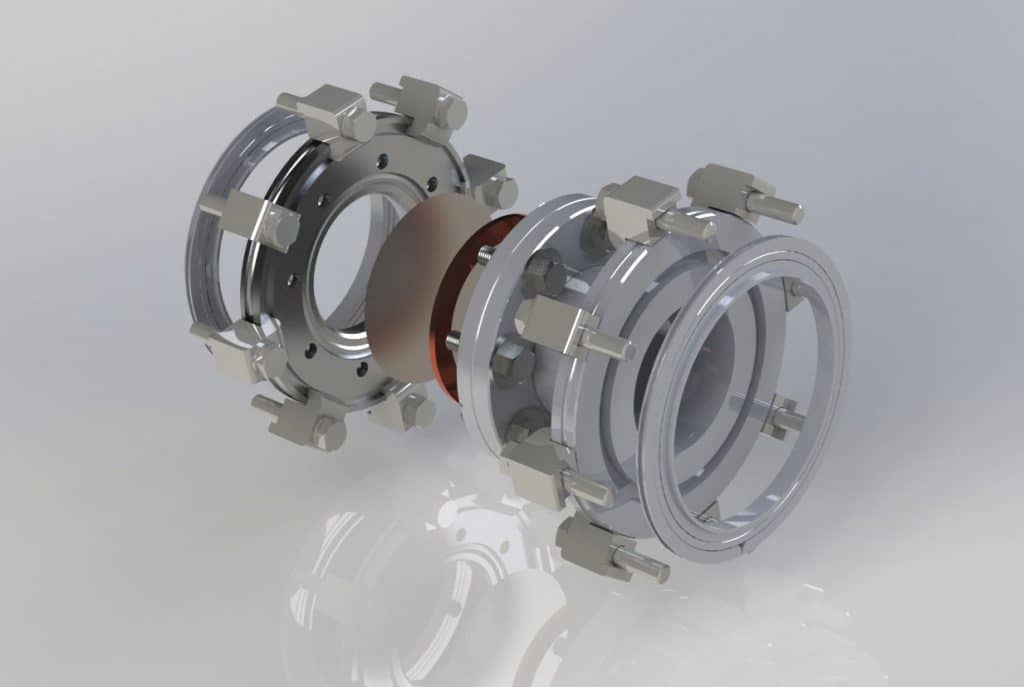

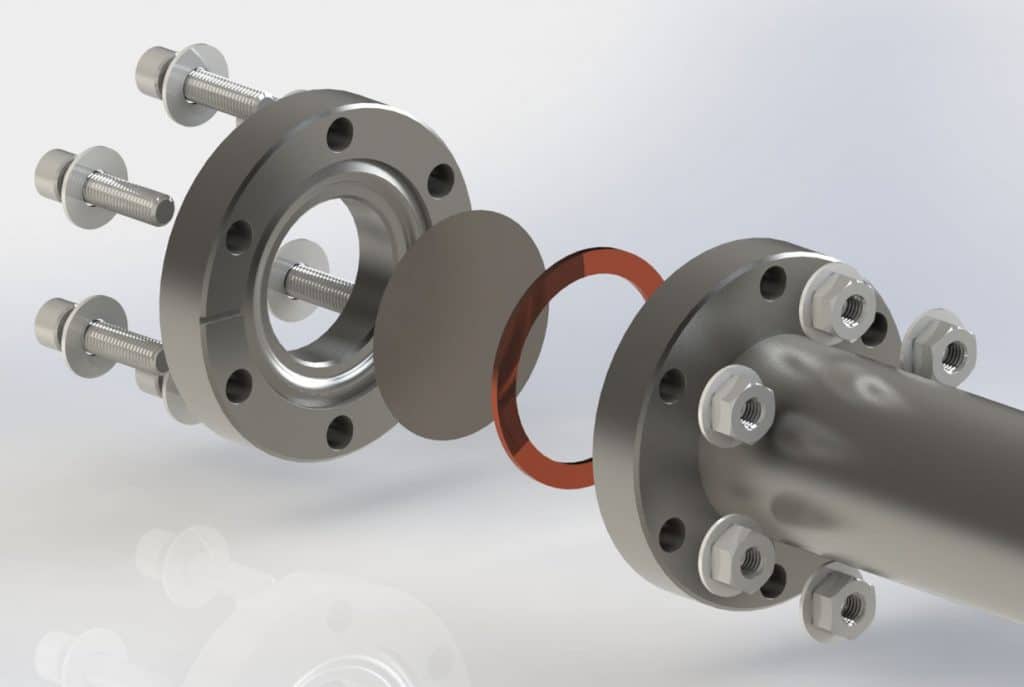

Window metals made into a thin foil can be gripped by the Foil-Window Flange (FWF) . The pressure differential on each side of the foil allows the FWF to grip the foil into a drum-like tensioned head made of a thin foil trapped between the FWF and a standard CF copper gasket. When connected to a vacuum conduit, the FWF isolates two vacuum regimes.

Foil Window Flanges can be used to prevent downstream failures to isolate different upstream vacuum regimes (i.e. Extreme High Vacuum XHV from High Vacuum HV).

The foils are low cost and user-replaceable, enabling customers to determine minimum thickness through experimentation quite inexpensively. Brazed windows, on the other hand, discourage users from achieving minimum thicknesses because of the risk and cost of trial and error.

- Quick and inexpensive replacement on site.

- Eliminates the need for a fixed, brazed assembly.

- Retrofits with standard CF flanges

- Alternative to beryllium.

- Transmission efficiencies determined by user.

- Vacuum may be applied in either direction.

Our growing list of customers, taking advantage of our foil window flange, include CERN, Notre Dame, Fermi Labs and more.

Scientific Papers (referencing foil stopping power and performance)

- Stopping Power and Scattering Angle Calculations of Charged Particle Beams through Thin Foils, A. Nassiri, ANL March 1991

- DESIGN OF HIGH PERFORMANCE SOFT X-RAY WINDOWS, Raymond T. Perkins. David D. Allred, Larry V. Knight, Department of Physics and Astronomy and Center for X-ray Imaging, Brigham Your University, Provo, Utah 84602, James M. Thorne, Department of Chemistry and Center for X-ray Imaging, Brigham Your University, Provo, Utah 84602

Foil Materials Available:

- Titanium Grade 2

Thicknesses:

- 127µm (0.005″)

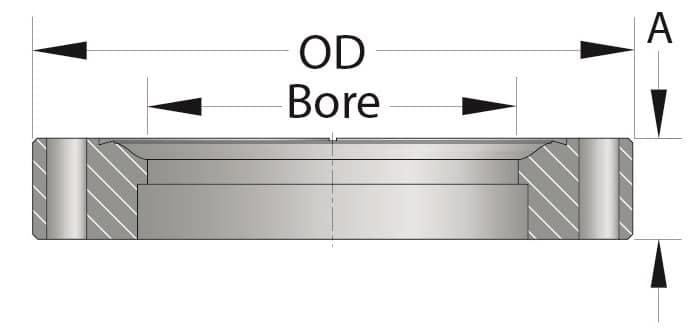

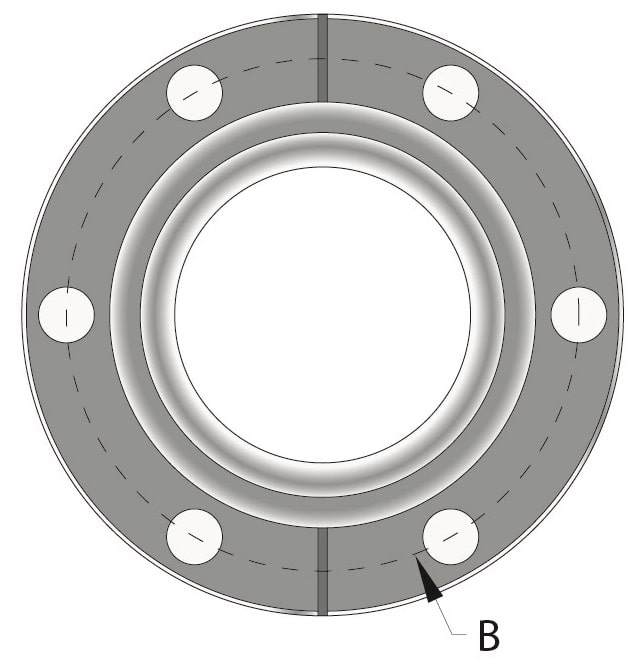

Diagrams & Variations

| Size | Bore | Holes | Hole Diameter | Thickness | Part # | Hardware | Files | Actions |

|---|---|---|---|---|---|---|---|---|

| 2.75" | 1.420" (31.5) | 6 | .265" (6.7) | 0.50" (12.7) | FWFSS-0275 | Show |

|

|

| 1.33" | 0.50" (12.7) | 6 | .172" (4.4) | .350" (7.2) | FWFSS-0133 | Show |

|

|

| 3.38" | 1.938" (49.2) | 8 | .332" (8.4) | .687" (17.4) | FWFSS-0337 | Show |

|

|

| 4.50" | 2.438" (61.9) | 8 | .332" (8.4) | .687" (17.4) | FWFSS-0450 | Show |

|

|

| 6.00" | 3.910" (99.3) | 16 | .332" (8.4) | .781" (19.8) | FWFSS-0600 | Show |

|

|

| 8.00" | 5.875" (49.2) | 20 | .332" (8.4) | .875" (22.2) | FWFSS-0800 | Show |

|