Aluminum’s Extreme Vacuum Performance

Any single physical or chemical property of aluminum may be enough reason to select aluminum as a vacuum chamber choice over stainless steel. But when looked at in summary, aluminum overwhelmingly surpasses stainless steel as providing the lowest cost of ownership. Aluminum has seven orders of magnitude less hydrogen than stainless steel. It has very low levels of Carbon, resulting in significantly less H2O, CO, C2 and CH4 than stainless steel. Aluminum vacuum systems require far less pumping than comparably equipped stainless steel chambers. A baked aluminum chamber has an outgassing rate of less than 1×10-13 Torr liter/sec cm2 compared to Stainless’ 6.3 x10-11 Torr liter/sec cm2 (1).

An aluminum chamber processed according to Atlas specification AVSP-08, entails cleaning and baking surfaces to facilitate the formation of a dense oxide passivation layer through the conversion of hydroxides into stable oxide molecules. The resulting surface inhibits the diffusion of other contaminants, further reducing pumping requirements—and faster pumping equates to smaller and less expensive pumps.

Fluorine gas is a common cleaning agent in aluminum chambers. Atlas aluminum chambers and gas delivery lines are far more resistive to fluorine than those made of stainless steel, because Atlas’ AVSP-08 process forms a dense protective oxide layer that make our aluminum a highly corrosion resistant material. These surfaces can be further protected from halogens by producing even thicker and harder oxide layers through an electrolytic anodizing process.

Excellent thermal properties such as high conductivity make aluminum an excellent vacuum material. With 10x the thermal conductivity, 21x the thermal diffusivity of stainless and extremely low thermal emissivity rates, aluminum chambers bakeout quickly and evenly. The surface properties of aluminum allow full bakeout at 150°C — much lower than stainless. Aluminum chambers heat up quickly and uniformly, bakeouts are faster and more complete with significantly reduced cycle times.

With low nuclear activation, aluminum has a short neutron activated half-life measured on a scale of hours—significant when compared to stainless steel’s scale, which is measured in thousands of years. This offers huge disposal savings and a priceless reduction in potential exposure to staff.

Aluminum is essentially magnetically transparent (non-magnetic). An aluminum UHV chamber’s low magnetic permeability offers no measurable disruption to electron and ion optics.

With a low Young’s’ modulus (69GPa) of elasticity (1/3 that of stainless steel, 207GPa) aluminum offers outstanding vibration dampening, making it the material of choice for precision synchrotron, semiconductor and physics applications where excess vibration can have disastrous consequences.

Compact aluminum vacuum chambers with up to 40% smaller footprints are economical alternatives to bulky stainless steel systems, especially when valuable floor space is at a premium. At about 1/3 the weight of stainless steel, aluminum chambers are significantly lighter and require less expensive support structures. Lower weight translates into reduced shipping costs and faster installation times.

Because of its superb machinability (5x to 10x faster than stainless) aluminum chambers can be manufactured with more detail. Aluminum can also be cut, shaped or formed, and extruded quite easily. Chamber features are produced to fit an application rather than tailoring an application to fit a material’s manufacturability limitations—reducing extra equipment and space.

Atlas offers five basic aluminum chamber types… monocoque, plate, tube, extruded and formed aluminum configurations, to give you a variety of design options and complete control of your application.

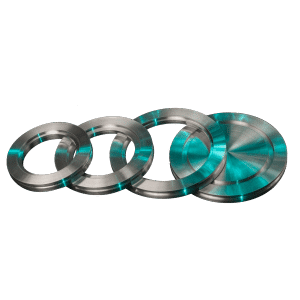

After weighing all factors, Atlas aluminum vacuum chambers can save 40% to 60% when compared to stainless—and the bigger the chamber, the more pronounced the savings—plus when fitted with Atlas CF Flanges, ATCR fittings and treated with AVSP-08, cost less than comparably equipped stainless systems. Cost savings are directly attributed to aluminum’s machinability; reduced outgassing volume and surface area; fast cycling, bakeout and pump-down times; reduced footprint and smaller/lighter support structures; reduced shipping cost; and lower disposal costs when dealing with nuclear activation applications.

Aluminum’s Extreme Vacuum Performance Delivered

Atlas has overcome the three major obstacles that have inhibited the use of aluminum in extreme vacuum applications… vacuum sealing, vacuum welding and vacuum surface passivation. Applying our knowledge and proprietary technology we produce state-of-the-art aluminum vacuum chambers that deliver the revolutionary physical and vacuum properties of aluminum at dramatic cost savings.

Footnotes :

- Chen, J.R. et al. Thermal Outgassing from Aluminum Alloy Vacuum Chambers. Journal of Vacuum Science and Technology A 3. p. 2188.

- O’Hanlon, John. Ultrahigh Vacuum in the Semiconductor Industry, Journal of Vacuum Science and Technology A 12, p. 921.