Reduce Heat Transfer

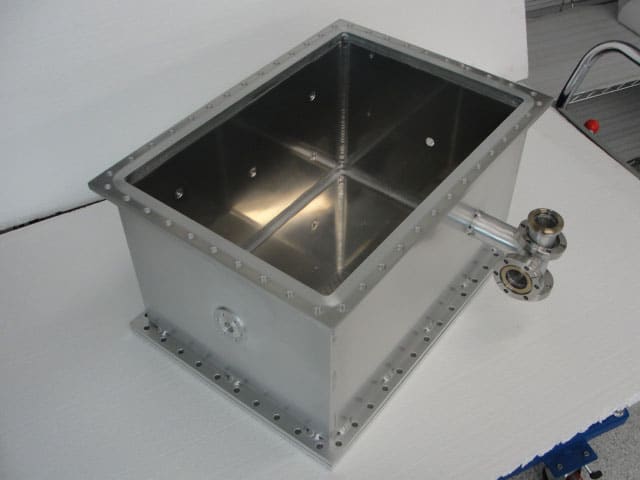

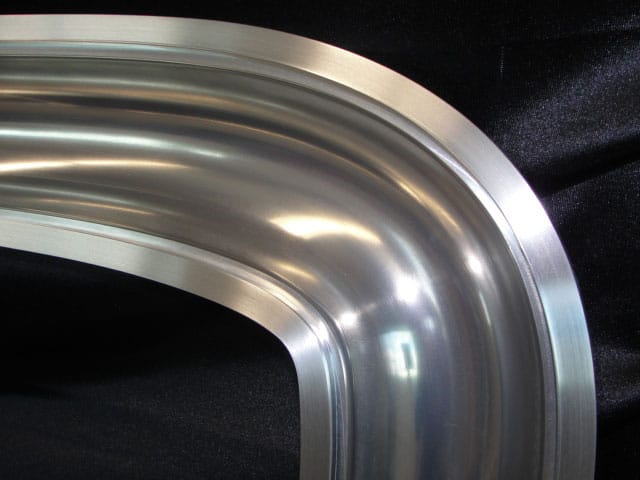

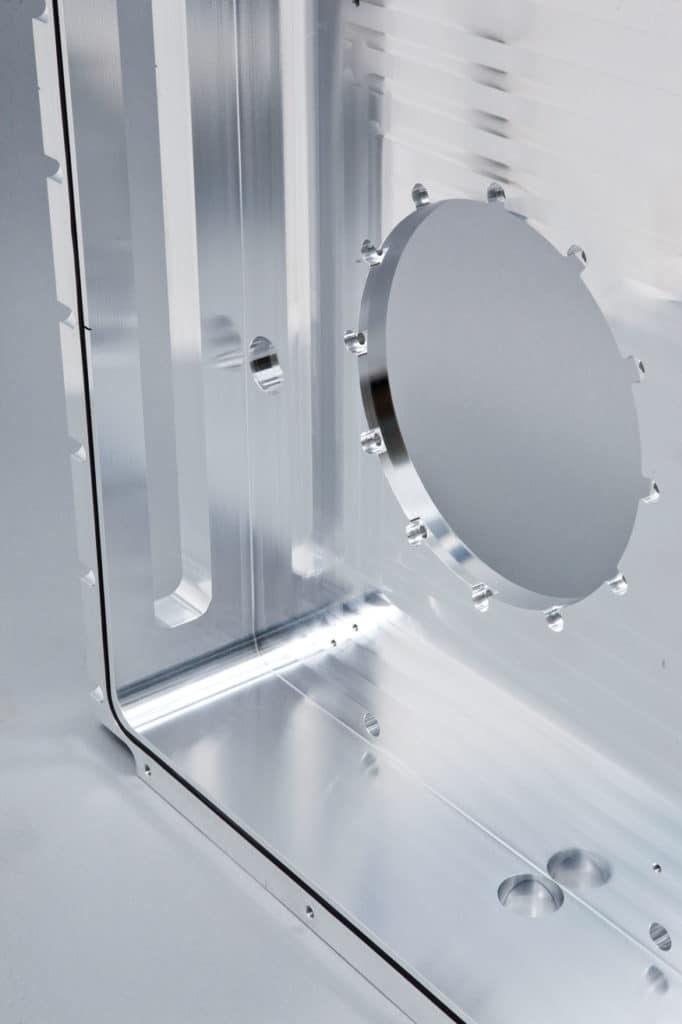

Atlas Emissivac polished surfaces have a considerably lower thermal emissivity than both unpolished aluminum surfaces and polished stainless steel surfaces. Emissivac vacuum chamber surfaces can insulate the cold portions of cryostats and dewars. Emissivac is also utilized to minimize the heat loss from objects in vacuum.

Heat Flux radiated from hot surface absorbed by a colder surface:

Q = σƐA(Th4 – Tc4)

Q = heater transfer per unit time

σ = 5.6703 10-8 (W/m2K4) – The Stefan-Boltzmann Constant

Ɛ = emissivity

Th = hot body absolute temperature (K)

Tc = cold surroundings absolute temperature (K)

Emissivity (Ɛ) of Aluminum & Stainless Steel at 300K1:

Weathered Stainless: .85

Rough Aluminum: .07

Polished Stainless Steel: .075-.162

Polished Aluminum: .039-.057

Improve Vacuum Performance

At extreme and ultra high vacuum, surface irregularities begin to play a larger role in affecting the quality of vacuum chamber performance. The Atlas Emissivac process reduces surface irregularities on the micro-scale. As the unevenness of the surface becomes smoother, the microscopic surface irregularities (which affect thermal outgassing and diffusion rates) decrease as a factor (f), know as the Darcy friction factor. This factor f seems to influence the vacuum quality by about 1 order of magnitude from one extreme to the other. Atlas Emissivac surfaces approach a factor of 1, meaning an exceptionally smooth surface.

Ultimate pressure:

p∞ = Q/S = ((qT + qd)Af + Qh + QST )/S

p∞ = Ultimate pressure

Q = Total outgassing rate

S = Pumping speed

qT = Thermal outgassing per unit area

qd = Diffusion rate per unit area

A = Surface area

f = Surface roughness factor