You've added an item to your quote. Edit quote

Atlas WS™ Wire Seal Flanges

To add this product to your quote cart or for CAD file access, please login or create an account.

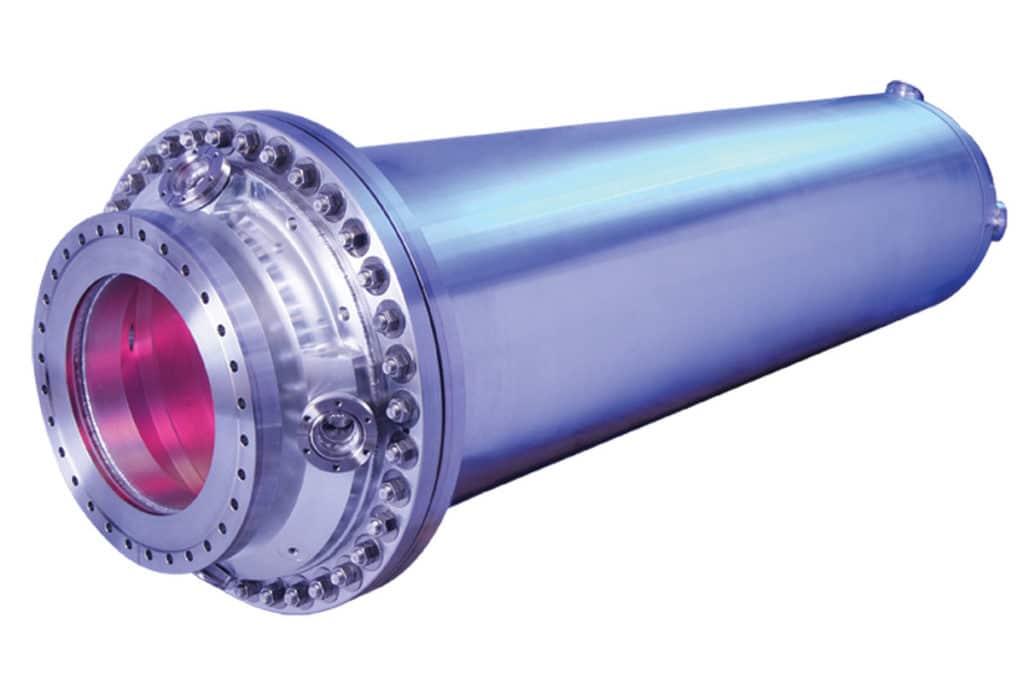

When size requirements for demountable flanges exceed that of standard Atlas CF™ flanges, Atlas Wire-Seal Flanges are the choice. These large, lightweight flanges enable you to utilize the many superior vacuum, physical, chemical, and nuclear properties of UHV aluminum vacuum chambers. Atlas Wire-Seal Flanges are made from large-area Atlas explosion-welded material.

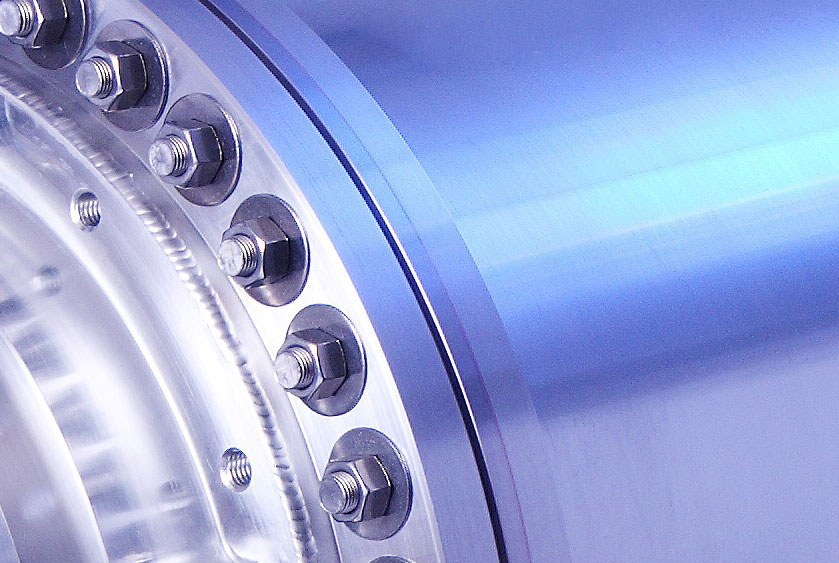

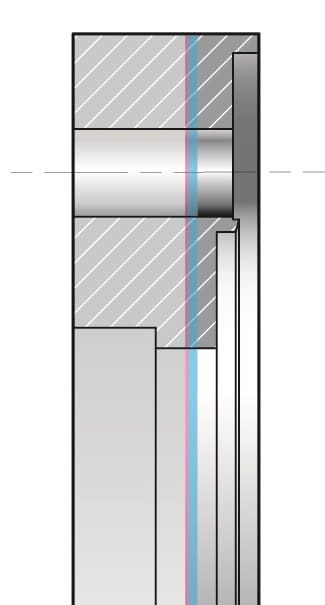

These flanges utilize a 316L stainless steel sealing surface to crush a wire gasket and a 6061-T6 aluminum flange body for weld-up to Atlas aluminum chambers. All Wire-Seal Flanges are vacuum tested and guaranteed leak tight to a rate of 1 x 10-9 cc/sec of He prior to shipping.

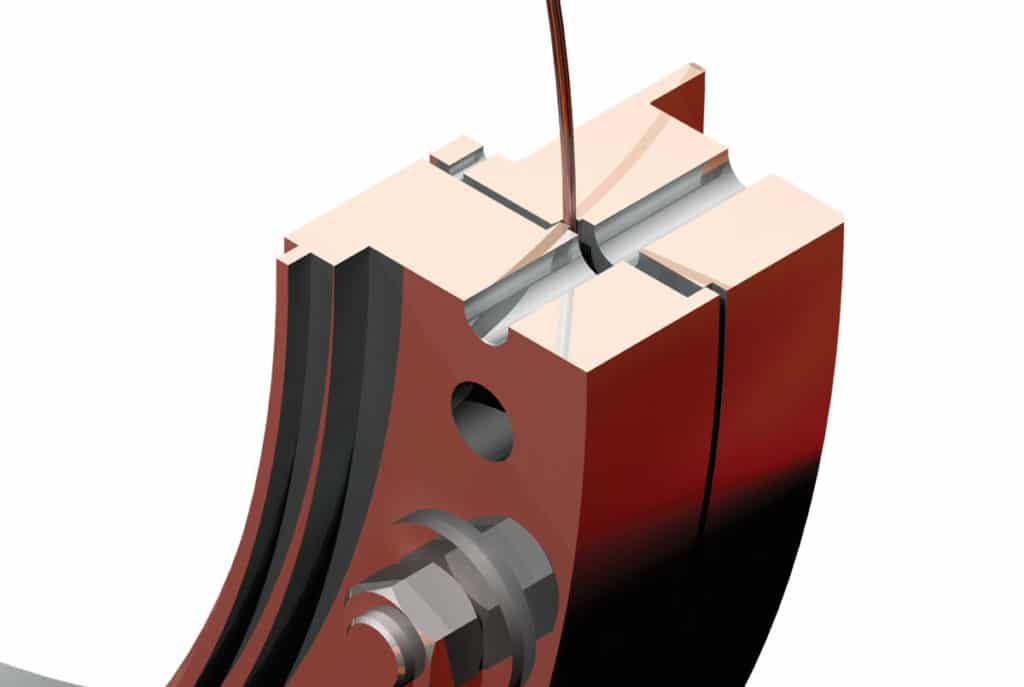

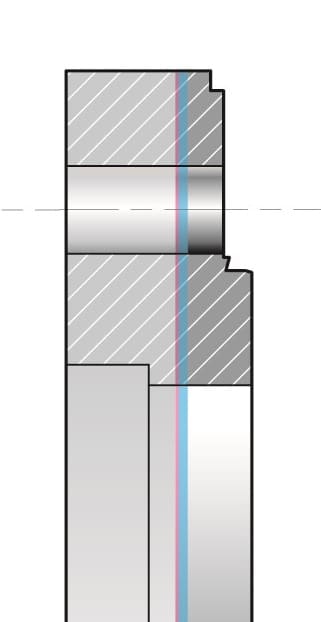

A male and female flange compresses a 0.080 inch diameter OFHC copper wire to affect a seal. A back bevel on the knife-edge improves the seal by making it more tolerant to thermal cycles, as well as enhancing its durability.

Please contact an Atlas salesperson for pricing and availability.

Material Choices

- Bi-Metallic Aluminum 6061 T6 bonded to 316L Stainless Steel

- Bi-Metallic Aluminum 6061 T6 bonded to Titanium Grade 2 used for non-magnetic environments

- All-Titanium Grade 5 is ideal to seal titanium vacuum chambers for non-magnetic and XHV vacuum regimes

Atlas Bi-Metallic Wire-Seal Flange Features

- Aluminum to stainless or titanium explosion welded (EXW) bimetallic construction.

- 1/3 the weight of stainless steel flanges.

- UHV/XHV rated to 1 x 10-13 Torr.

- 100% compatible with third-party stainless Wire-Seal hardware.

Environmental

- Vacuum leak tested to < 1 x 10-9 cc/sec of He

Thermal

- Peak Temperature (during weld-up) 300°C

- Operational Temperature from -200°C to 250°C

Mechanical (EXW Interface)

- Tensile—15,000psi

- Shear—10,000psi