Our customers at a large Midwestern research university needed a very thin titanium window for an electron optics application. The idea that they brought to us included a permanently brazed approach that was, unfortunately, thick and expensive to replace if the window failed. The customer wanted it thinner but found the risk of the part failing due to the force that brazing would exert upon it, less than ideal.

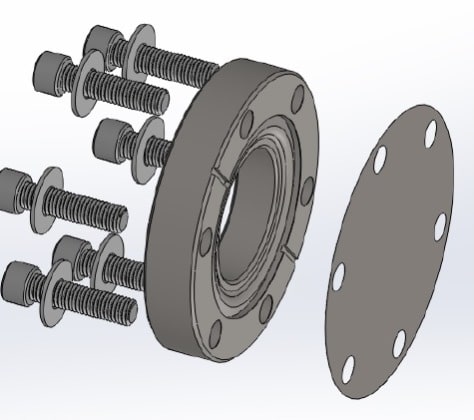

The ultimate solution, developed by Atlas, was a low cost replaceable and extremely thin (.002”) titanium UHV window trapped between a standard knife edge flange and, the now new product, an Atlas Foil Window Flange. See back page for more product information. Among other benefits: No Beryllium and Low Z

Solution: Foil Window Flange