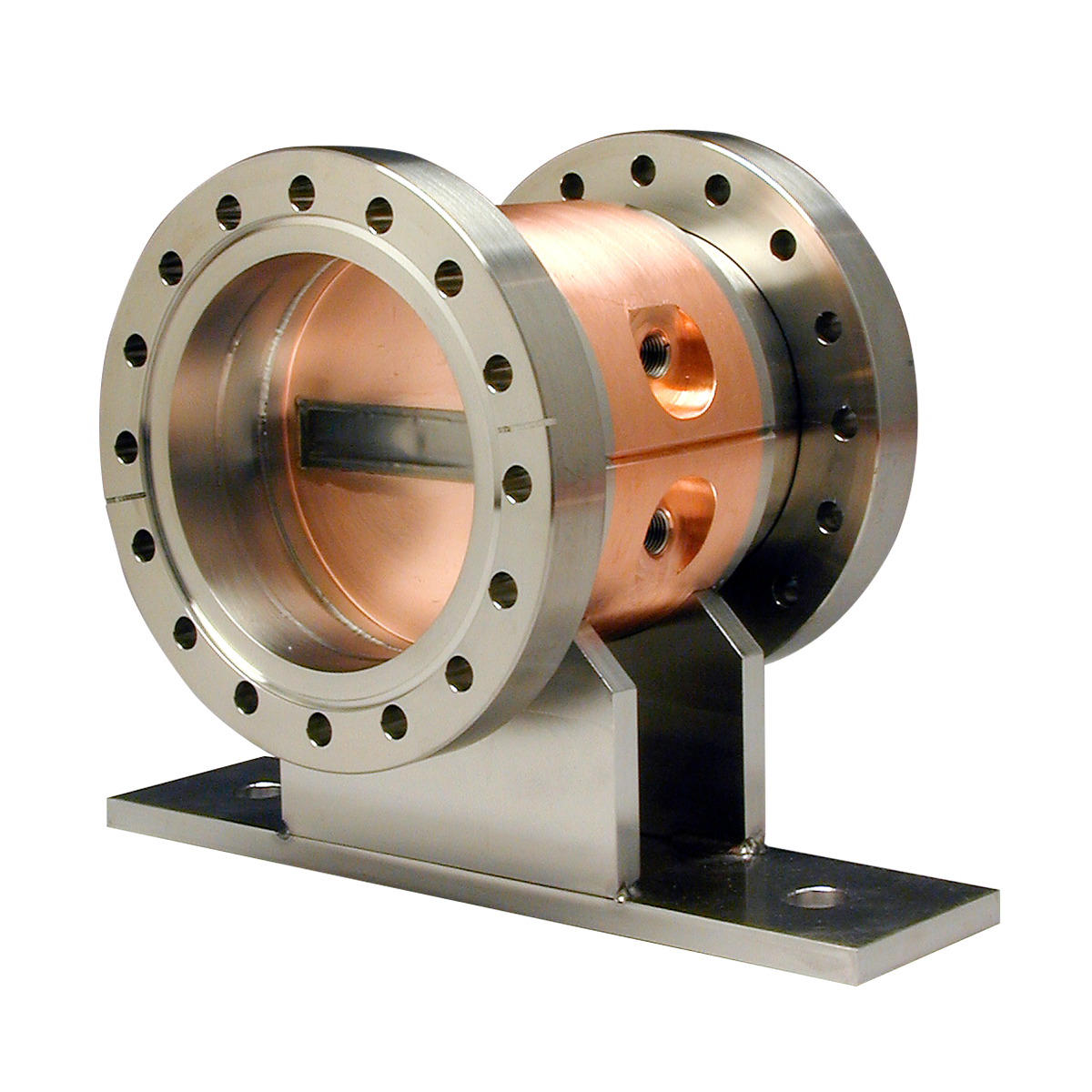

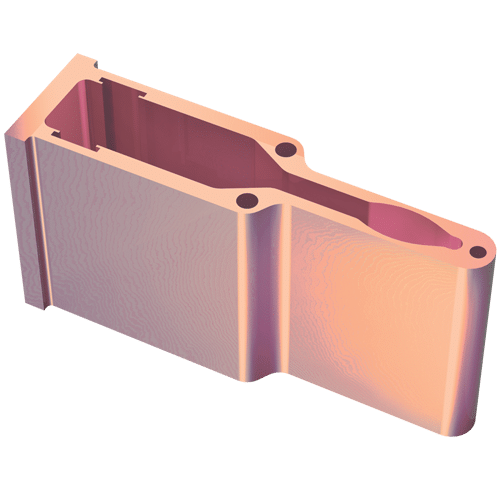

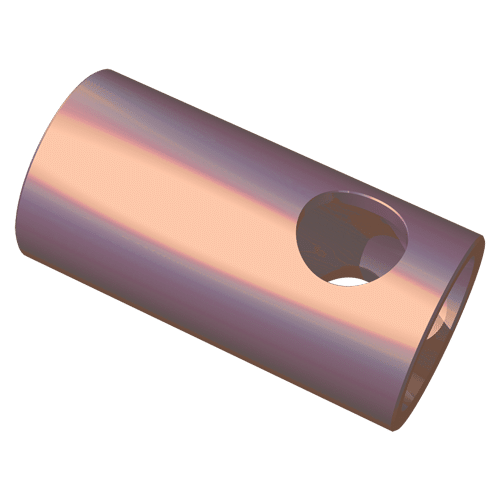

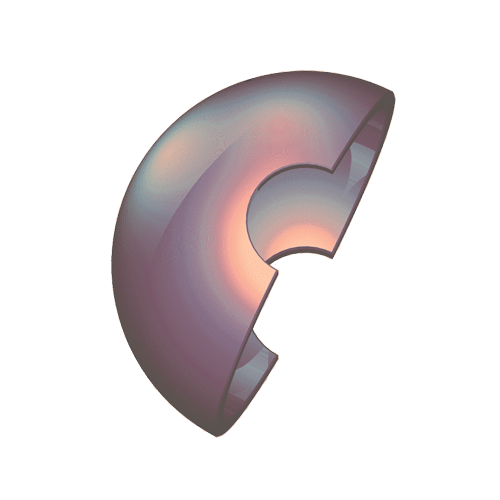

Copper Vacuum Chambers

Atlas Technologies is pleased to offer copper vacuum chambers and components for unique and challenging UHV vacuum applications.

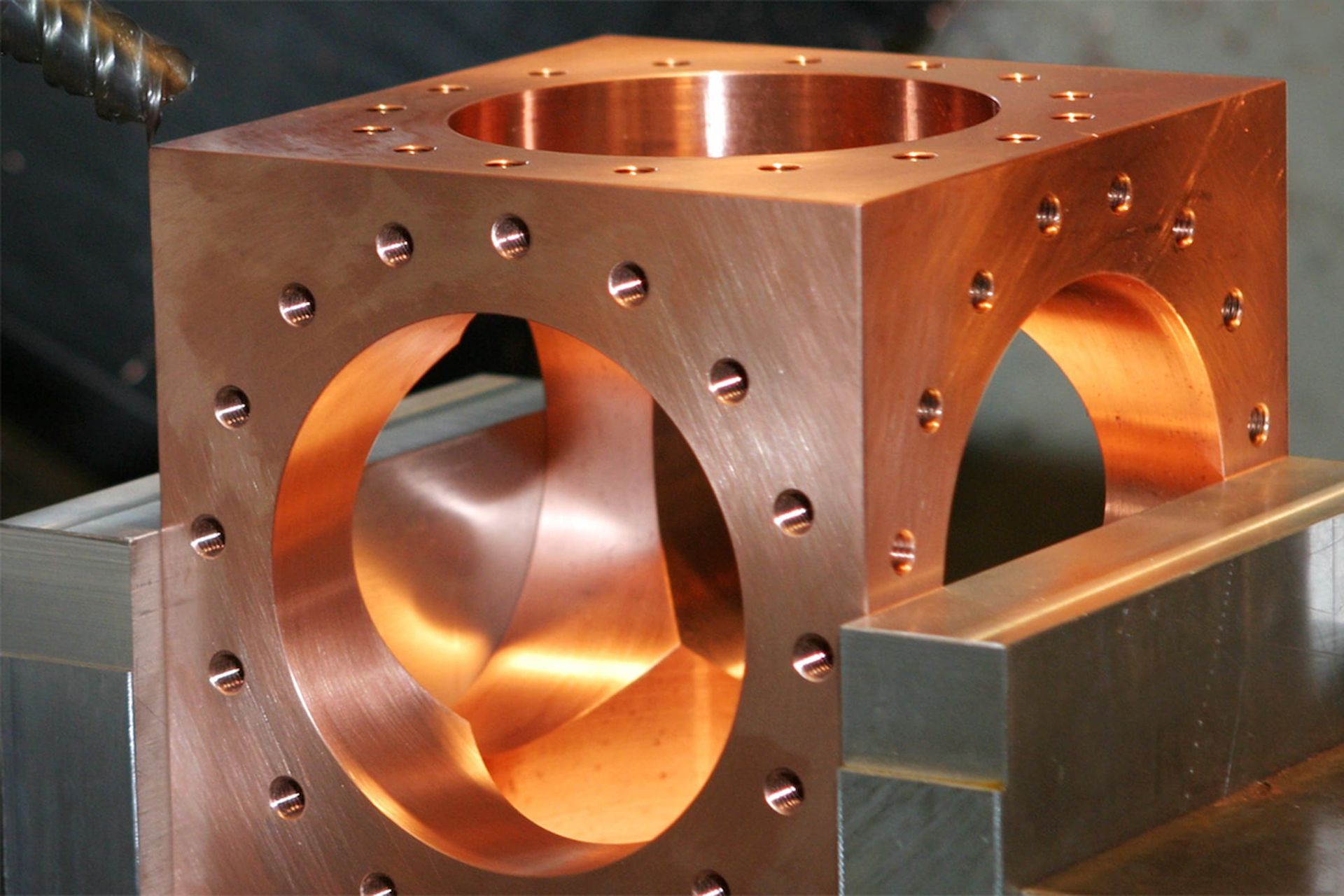

Oxygen-free copper alloys can be easily machined and have high corrosion resistance. With their exceptional thermal conductivity, copper chambers can be water-cooled for use in high-temperature applications.

Copper chambers are non-magnetic and are often used in RF applications. Copper has excellent electrical characteristics and can handle high heat loads when sufficiently cooled, making it a great choice for accelerators.

With its good formability, copper can be machined, extruded, brazed, welded, or soldered.

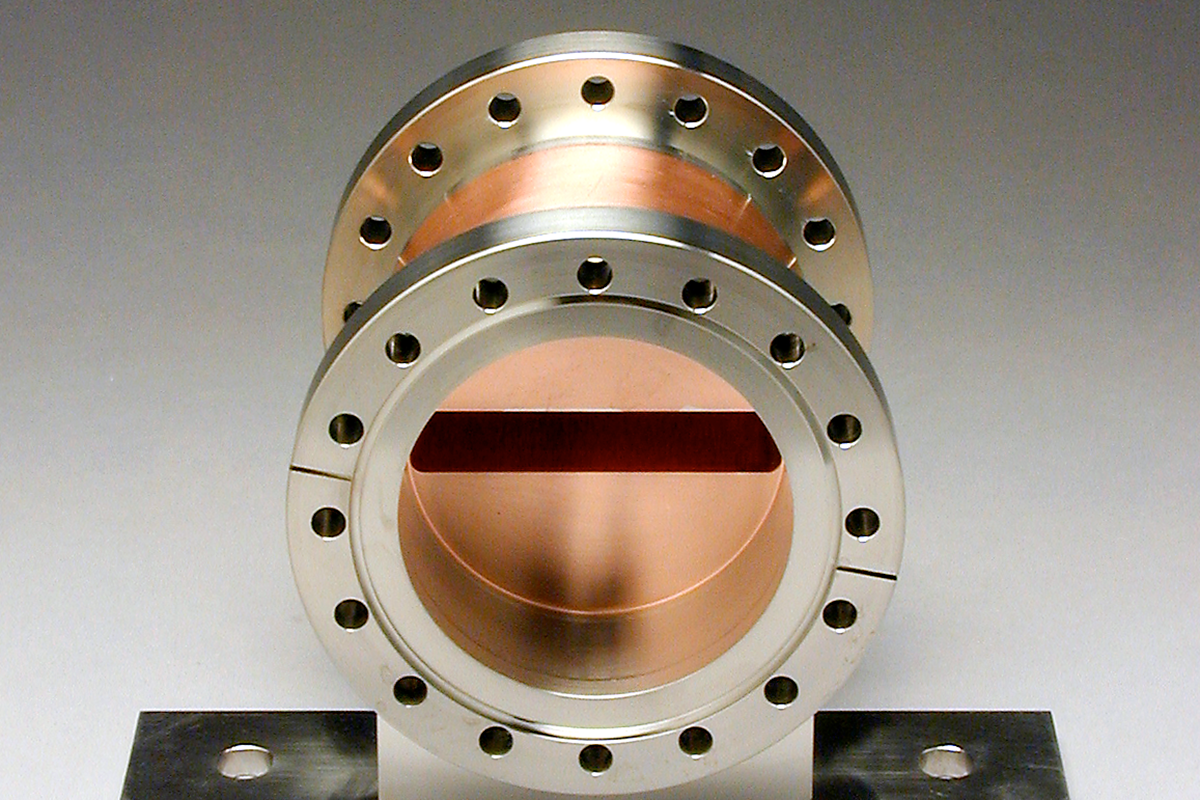

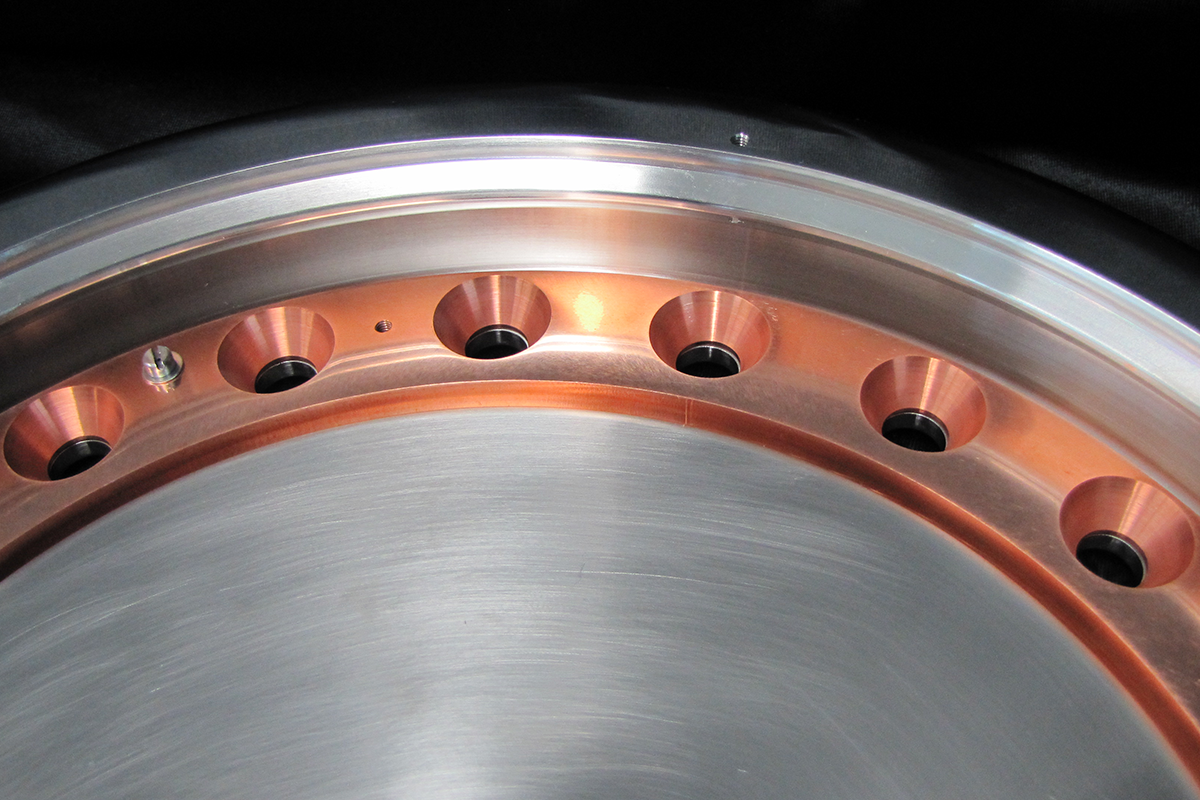

Atlas manufactures bimetallic Copper/Stainless CF Flanges which have a stainless steel sealing face on a copper body. The stainless face matches the coefficient of thermal expansion of other stainless flanges, while the copper body allows for welding to a copper chamber. For completely non-magnetic applications, copper-to-copper vacuum seals can be made with specialty flanges or hardened copper alloys.

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a napkin sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.