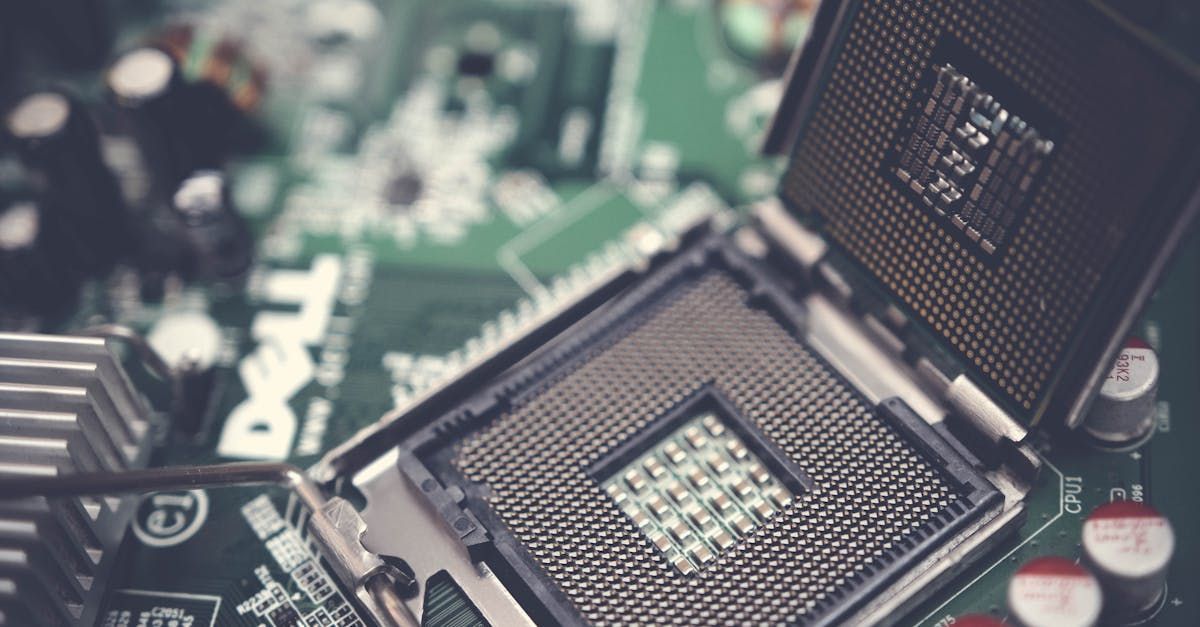

SEMICONDUCTOR

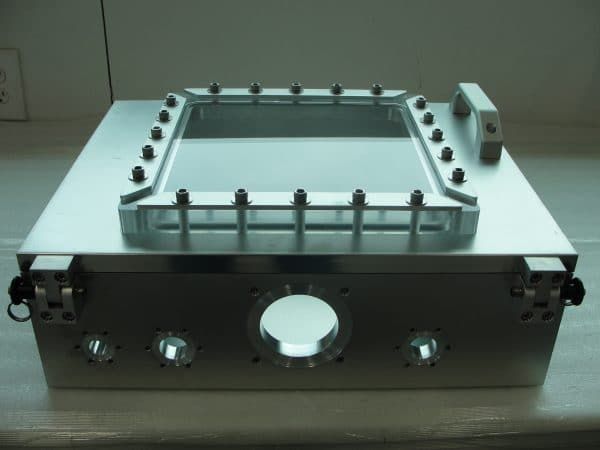

ATLAS CHAMBERS & FLANGES FOR UHV/XHV & UHP APPLICATIONS

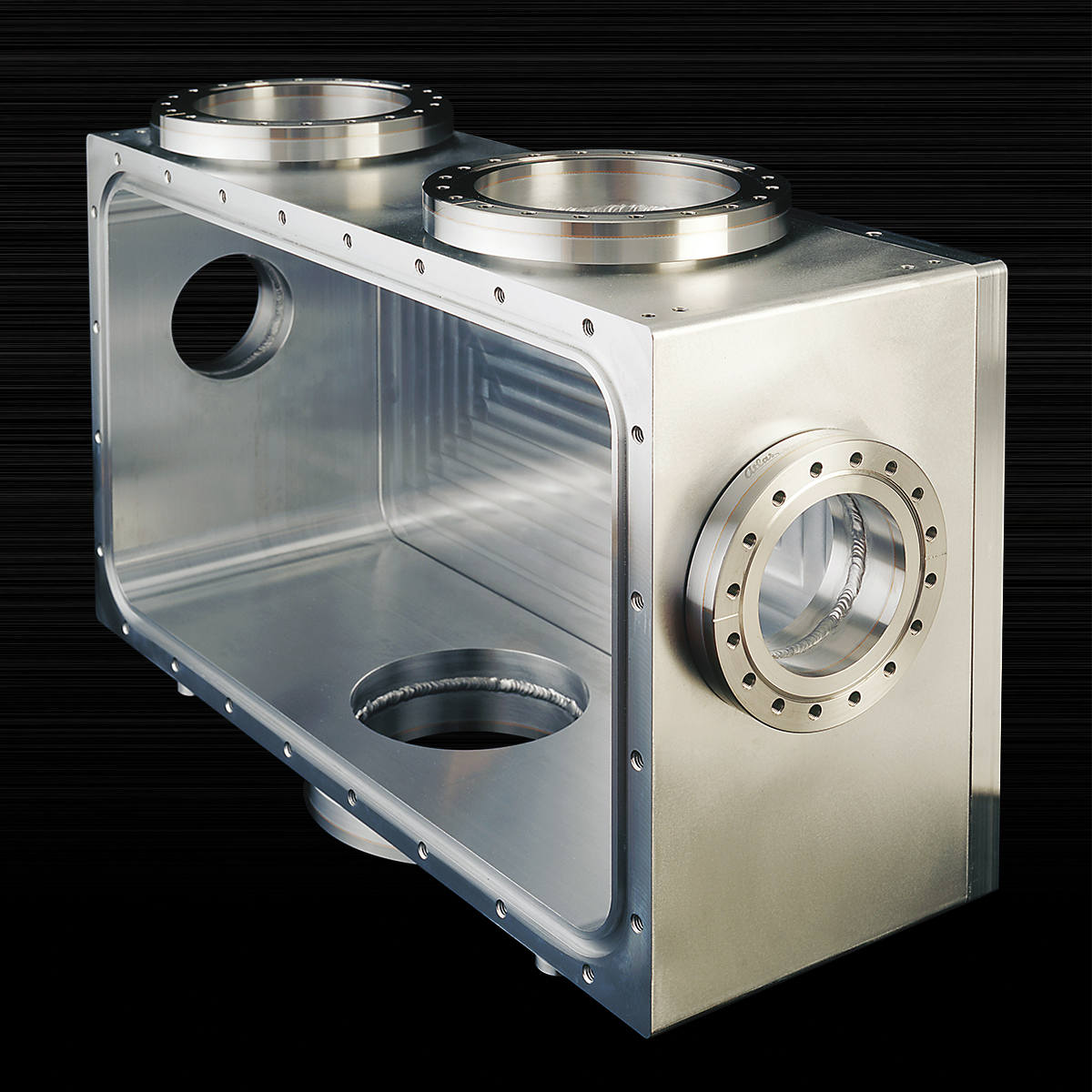

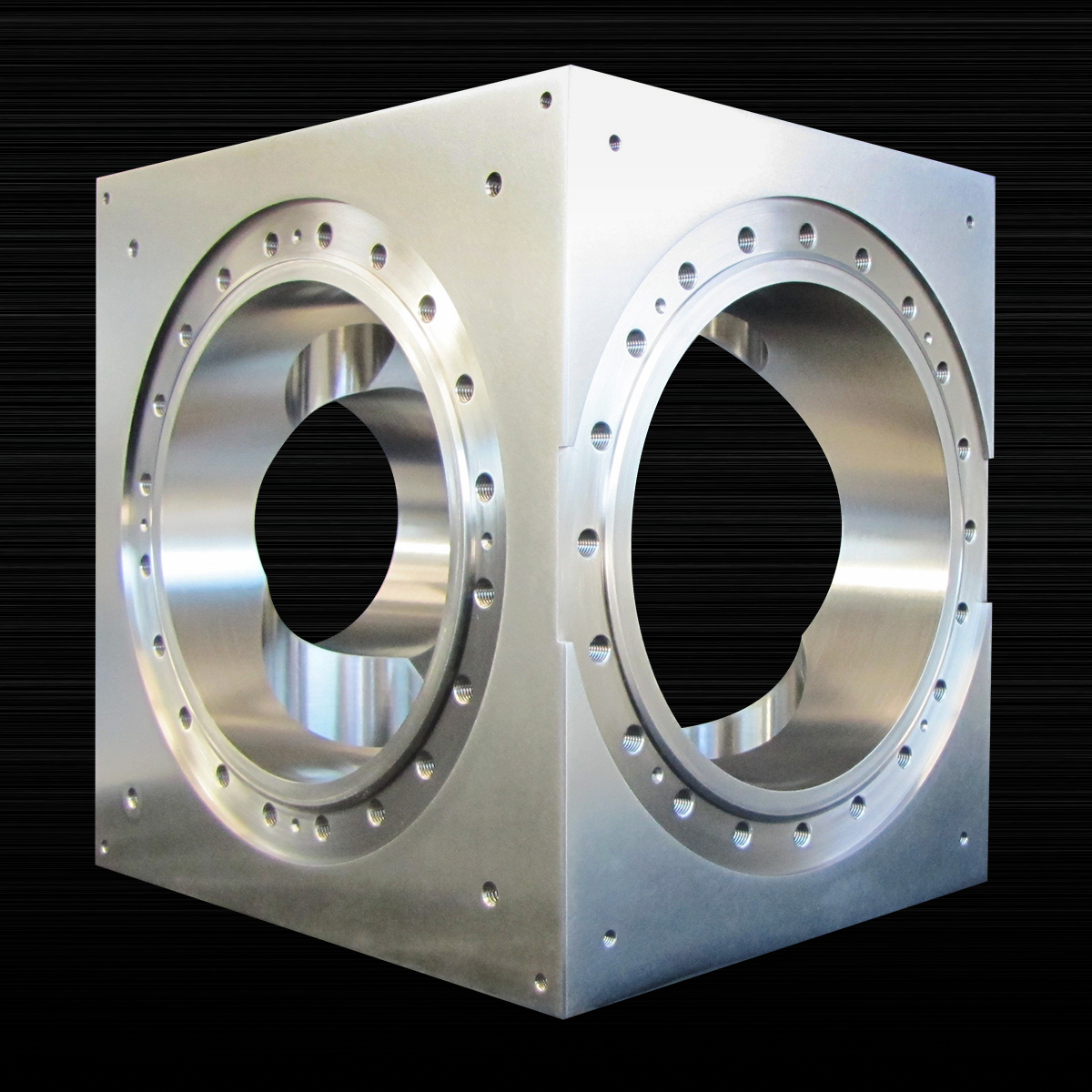

Nearly all processes in semiconductor manufacturing require the low-pressure, contamination free environment found inside a vacuum chamber. While many operations rely on stainless steel vacuum systems, Atlas custom aluminum and titanium vacuum chambers offer benefits especially important for ultra-high vacuum (UHV), extra-high vacuum (XHV), and ultra-high purity (UHP) applications.

REDUCED CONTAMINATION. INCREASED PERFORMANCE.

For deposition processes, complex etching, ion implantation, and wafer handling, Atlas chambers ensure precise control and significantly reduced contamination.

Both aluminum and titanium offer low, or no, hydrogen and carbon contamination, high thermal conductivity, a non-magnetic environment, and lighter weight than stainless steel. As outgassed carbon can be a serious source of contamination, potentially damaging optics used in semiconductor lithography, aluminum and titanium vacuum systems with no carbon, provide a solution. Aluminum and titanium also offer excellent thermal control for wafer processing.

ATLAS VACUUM CHAMBERS AND BIMETAL FITTINGS ARE USED IN:

- Chemical and physical vapor deposition (CVD/PVD)

- Wafer manufacturing, processing and movement

- Etching and lithography

- Ion implantation

- Packaging leak testing and control

- Emerging technologies and processes

HV, UHV, XHV & UHP solutions

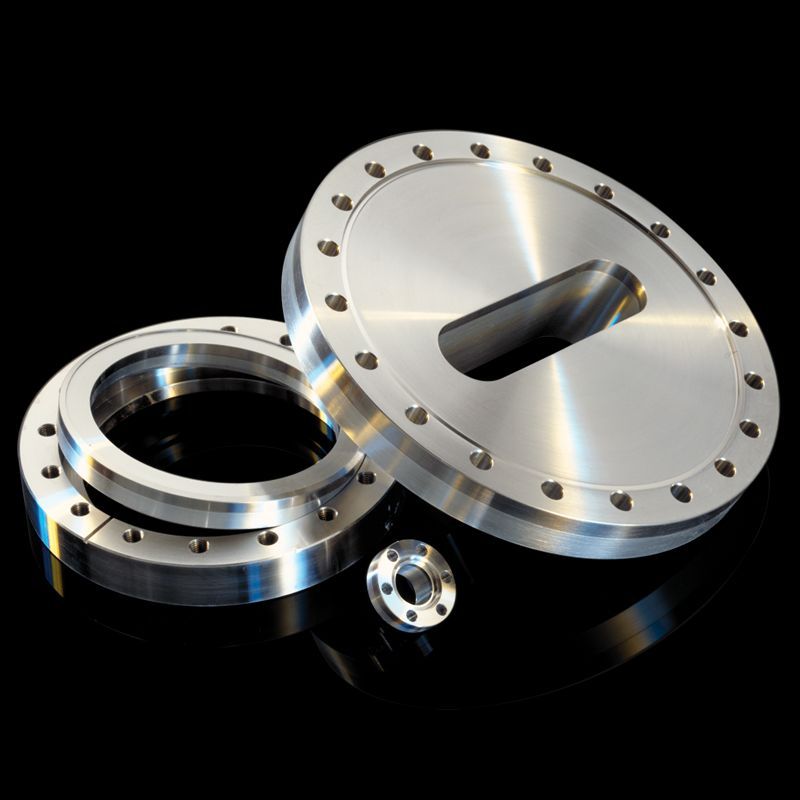

Atlas builds aluminum HV, UHV, XHV and UHP chambers for facilities seeking the highest levels of performance and cleanliness. The chambers can be sealed with rugged Atlas TI/SS and Al/SS flanges with a stainless knife-edge to connect to the larger system.

Our semiconductor OEMS and customers come to us for help designing and manufacturing complex solutions that need to perform relentlessly. Come talk to us about your next engineering challenge.

HOW CAN WE ASSIST IN YOUR NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a rough sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.