Dissimilar Metal Bonding and Joining

With our extensive experience in bonding and joining a variety of metals, we are able to help our customers take advantage of the complex and sometimes competing material properties to achieve the result they are looking for.

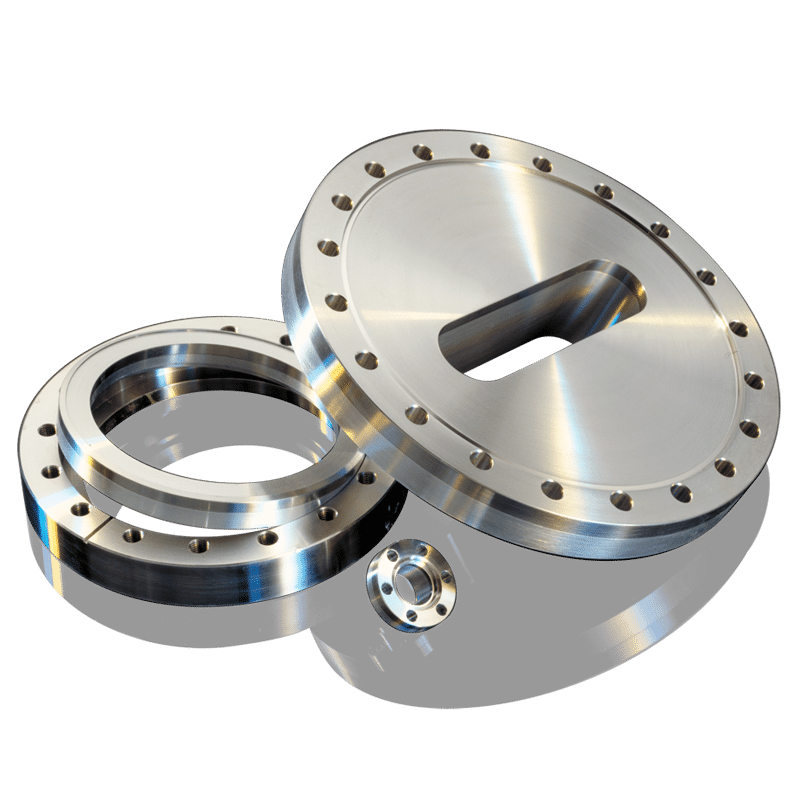

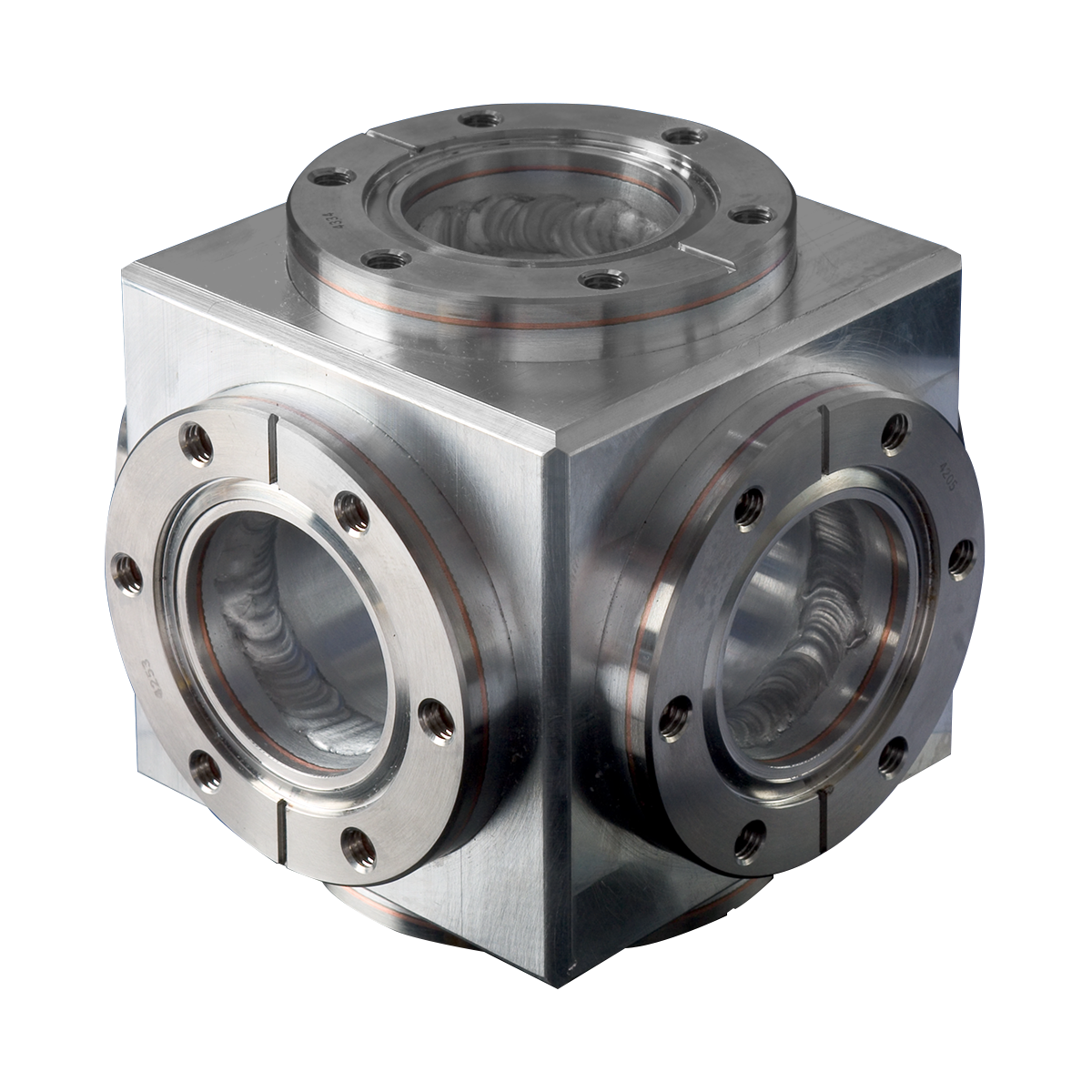

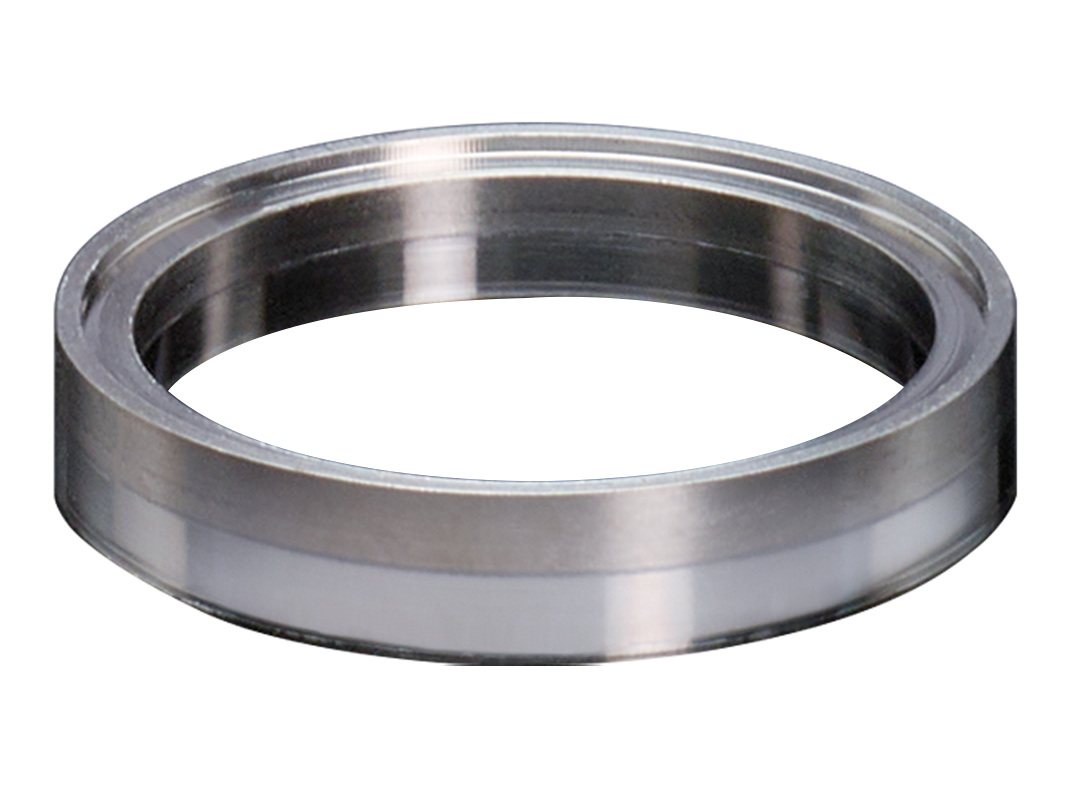

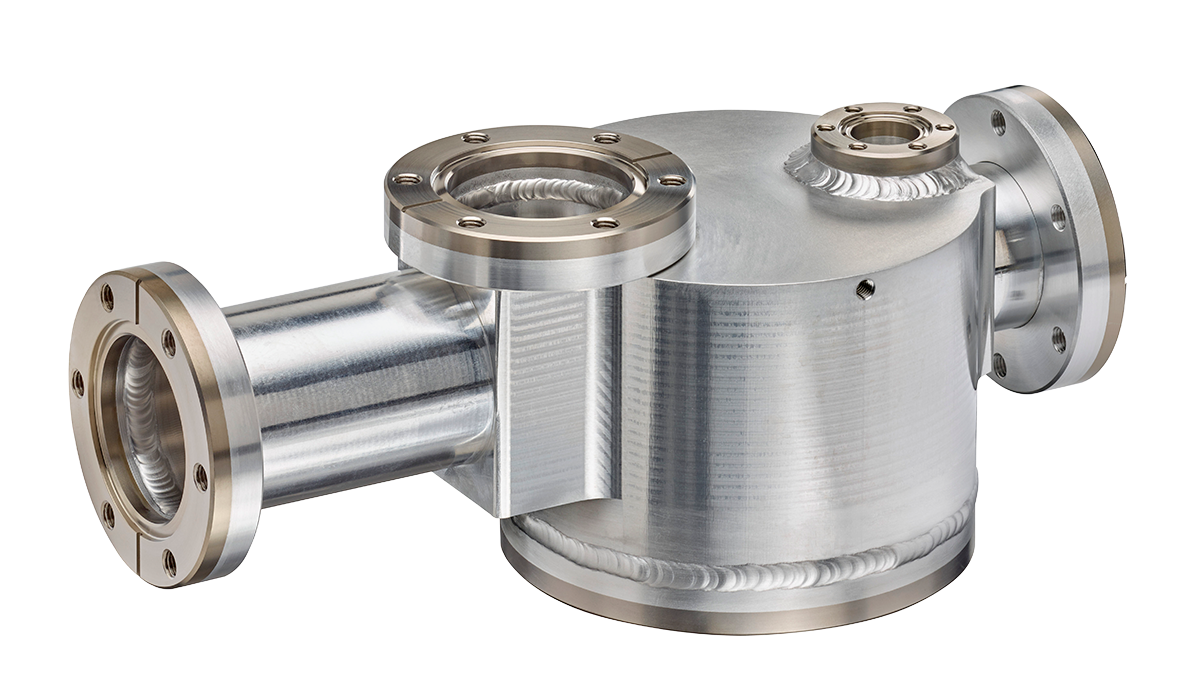

Our high-performance solid-state bonds excel in the most demanding applications including UHV and XHV vacuum, difficult to seal locations, extreme temperatures, chemically corrosive environments, underground and in outer space. Our components are used extensively in semiconductor fabrication, particle physics, medical, nuclear, cryogenic, oil and gas, and many other industries.

Much of what we do involves custom bimetallic solutions for our clients. We work closely with engineers and product developers to understand specific needs and ideal outcomes. to deliver a high-performance solution for every project.

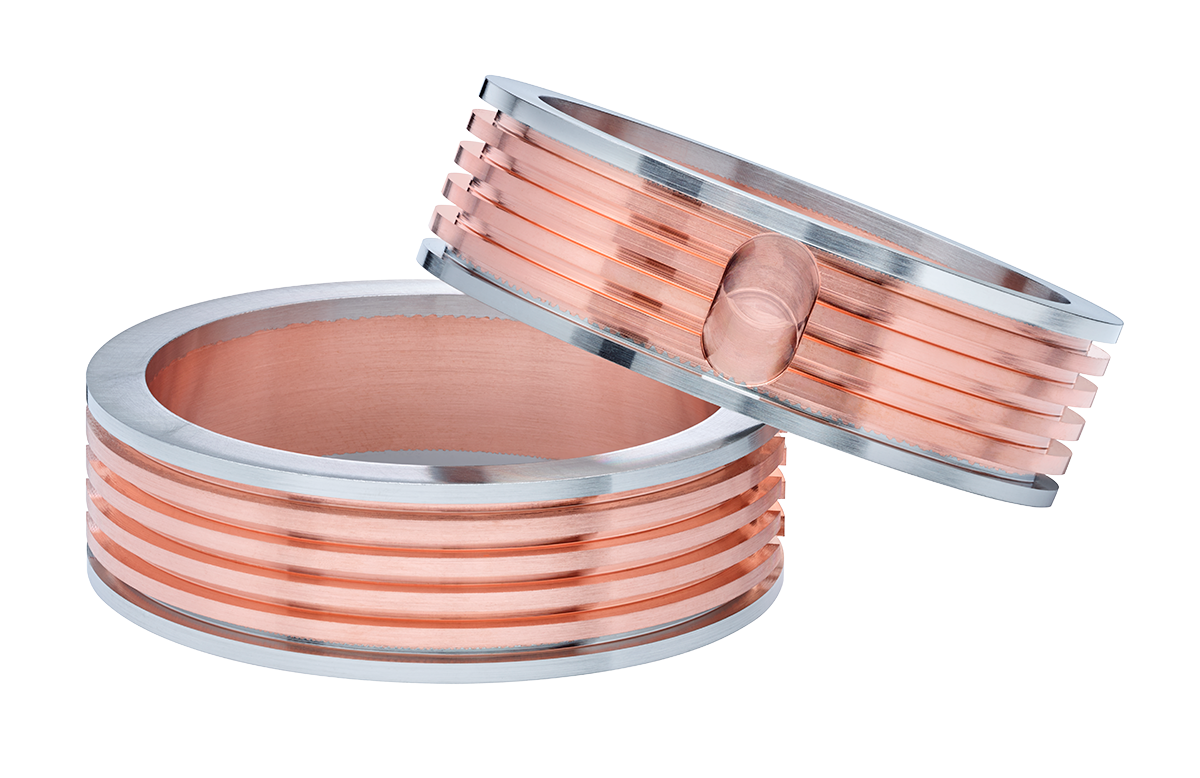

Often our explosion bond tensile strength exceeds the strength of the weaker of the two parent materials. The bonds feature a natural wave pattern that increases the surface area, which in turn increases strength and heat transfer across the bond.

Atlas regularly bonds and machines these dissimilar metals and we’ve found them to perform exceptionally well in a variety of demanding applications.

| Metal A | Metal B |

|---|---|

| Aluminum | Stainless Steel |

| Aluminum | Copper |

| Aluminum | Titanium |

| Titanium | Stainless Steel |

| Titanium | Copper |

| Niobium | Stainless Steel |

| Stainless Steel | Copper |

Some combinations require the use of a transitionary interlayer to circumvent metallurgical incompatibilities between parent materials.

Looking for another combination? Contact us. We’ll be happy to explore additional options to support your project.

A few of the bonded metal properties that can be applied:

- Metals capable of maintaining mechanical strength at extremely high or cryogenically low temperatures

- Metals with high thermal conductivity versus others with insulative properties

- Metals with excellent strength-to-weight ratios compared to those with greater strength but with added weight

- Metals undamaged by specific chemical or environmental exposures versus those that quickly corrode in the same applications

- Metals that attenuate vibration and others that ring like bells

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a simple sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.