MACHINING & WELDING

WELDING ALUMINUM IS A LITTLE DIFFERENT. Download our handy welding guide here.

precision Metal fabrication

Our specialty is bonding dissimilar metals and then machining, welding, finishing and testing them to ensure exacting performance in critical environments including aerospace, particle physics, semiconductor fabs and more.

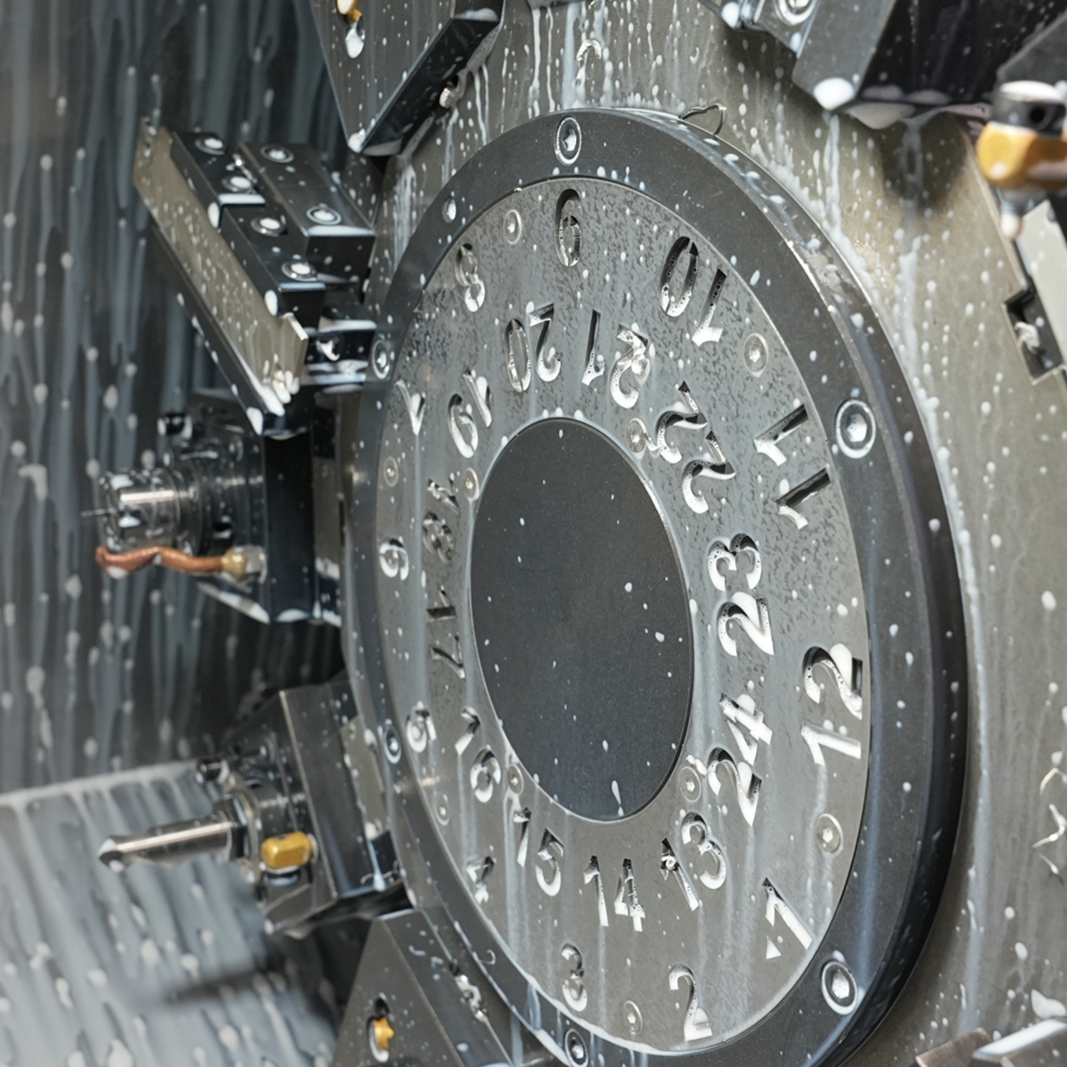

3 | 4 | 5 axis CNC milling

| Machine | X-Axis | Y-Axis | Z-Axis |

|---|---|---|---|

| CNC Boring Mill (19” width) | 78.7” | 59” | 78.7” |

| 3 Axis Mill | 40” | 20” | 20” |

| 3 Axis Mill (4th axis capable) | 96” | 54” | 31” |

| 5 Axis Mill (32-position tool changer) | 35.4” | 30.7” | 25” |

CNC Lathes

| Max Turning Diameter | Chucks | Live Tooling |

|---|---|---|

| 14.8” | 10" main / 8" sub spindle | BMT65 |

| 13.8” | 6” / 16c collet | BMT45 |

| 14.75” | 10" | VDI |

UHV Quality Welding

Our customers require someone capable of welding aluminum and titanium vessels that perform flawlessly in UHV environments whether that's in a cryogenic chamber, a satellite, or a particle accelerator.

With our long history designing and manufacturing uncommon metals, all our welders are experts in welding challenging materials. They take great pride in laying down perfect stacked dimes as we call it, and address the special heat requirements of aluminum and copper, as well as the more well known stainless protocols.

• 700A and 400A welders

• Laser welder

• Experts in welding challenging materials

Leak Checking

All Atlas bonds and welds are leak tested to ensure performance in the most exacting circumstances.

- Pfeiffer ASM 392, ASM 340D & ASM340I leak check machines

- Multiple high capacity and turbo pumps for large chambers

- All managed to ensure calibration and control

- Bake-out and RGA capabilities on request

- Hydrostatic testing for water cooling channels

- Leak checked to minimum 1.0x10-9 Torr x L/second. Higher Torr rates upon request.

- Customer defined leak rate and max allowable pressure available.

Assembly & Chamber Processing

Our detail team offers the additional services

- Helicoil installation

- Installation of customer purchased chamber equipment and accessories including view ports, handles, hinges and feedthroughs

- Laser marking

- Leak check of customer provided manufactured parts

- Gasket installation

- Inspection of UHV critical features

- Assembly of chamber and chamber components

- Inner gasback filling

- Repair or rebuild and retest of process damaged items

- Inspection of outside processes to customer acceptance criteria

need help manufacturing a special chamber or component?

Machining and welding aluminum, titanium and bonded bimetals requires a higher level of expertise. We're not your typical job shop. We're here to help you design and manufacture your next UHV, XHV or other critical application.