CVD

Advanced Vacuum. Better Vapor Layers.

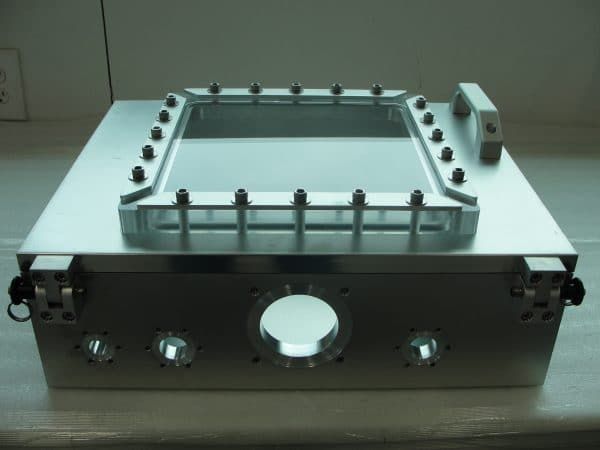

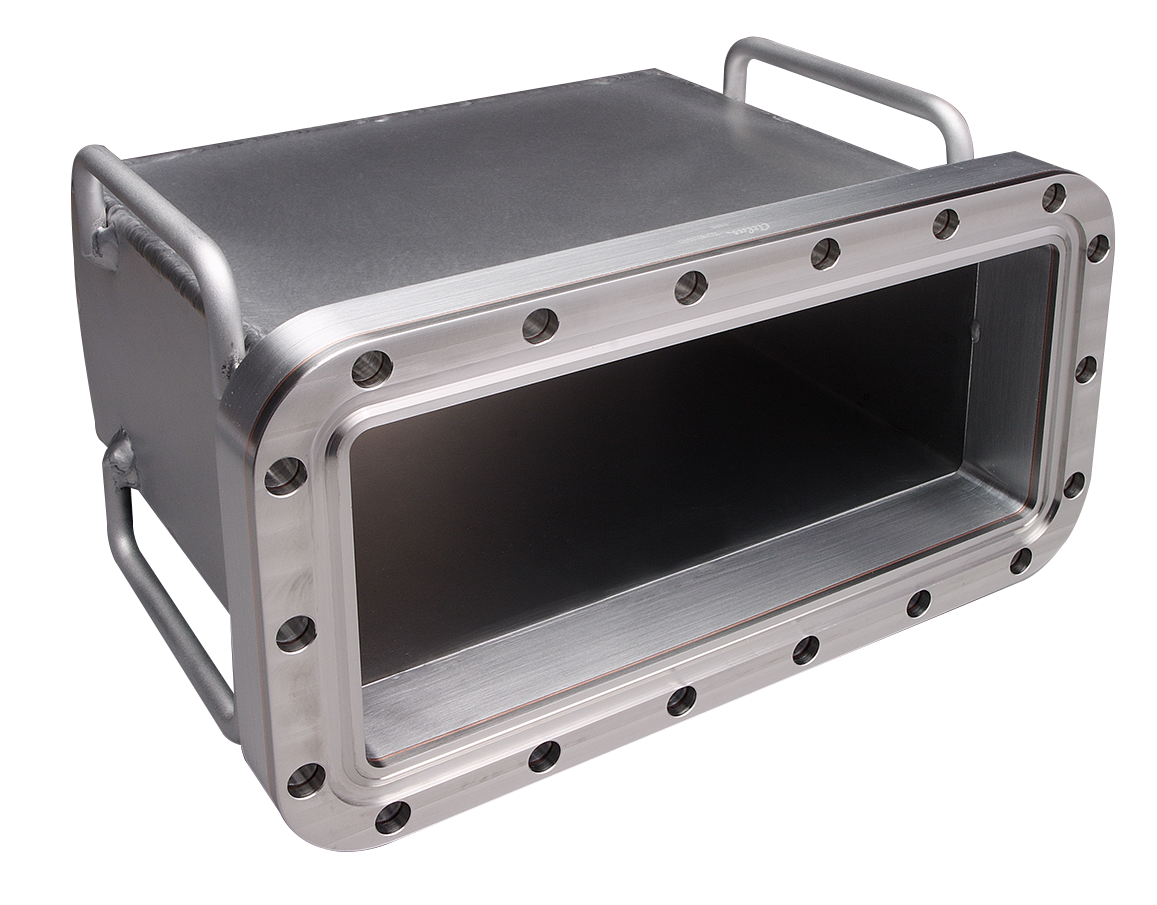

Whether used to produce thin film, synthetic diamonds, or automotive coatings, chemical vapor deposition (CVD) requires effective vacuum to produce resilient, high-quality finished materials. Atlas aluminum chambers with low carbon and hydrogen, excellent chemical resistance, and unmatched thermal efficiency get the job done right.

Clean, controlled conditions

Vacuum is critical for providing the clean, controlled conditions necessary for CVD applications. Atlas solutions are used for CVD across all sectors from semiconductor to energy, food packaging to medical equipment manufacturing. Aluminum and titanium chambers offer reduced contamination, handle greater heat cycling challenges, and due to their light weight, are easily maneuverable. Custom and standard bimetal fittings and flanges connect the chamber to the larger system.

Atlas CVD customer applications include:

- Semiconductor fabs

- Nanoscale and ultra-thin films

- Optics anti-reflective coatings

- Advanced photonic devices

- Thin film solar products

- Aerospace protective coatings

The answer to your CVD vacuum challenges

We help our CVD customers develop complex vacuum solutions for challenging applications in research, optics, crystal manufacturing, sterile surfaces, and more. How can we help you?