DISSIMILAR METAL BONDING

30 YEARS’ EXPERIENCE BONDING DISSIMILAR METALS

We began bonding metals in the nineties and our technology and expertise has only increased over the years. We regularly bond aluminum, titanium, niobium, copper, and stainless steel, as well as more exotic metals.

ENGINEERING BETTER PERFORMANCE

When designing complex, high-performance systems, there is often no single metal or alloy that perfectly satisfies all design requirements. Bonded dissimilar metals combine the advantages of two or more metal properties in one component. Whether you need to reduce costs, manage thermal properties, vibration, distortion, or weight, or build a more robust, corrosion resistant pipe transition, we can help.

Our bimetals are USED IN THE MOST DEMANDING APPLICATIONS

Atlas dissimilar metal bonds are mechanically robust, totally hermetic, and remain ductile in pyrolytic or cryogenic temperatures. With advanced solid-state bonding technology, a huge variety of metals can be joined and then be further machined and welded to adjacent metals.

The bonds are so strong and reliable, they are used in Ultra High Vacuum (UHV) and Extreme High Vacuum (XHV) applications for the semiconductor, chemical processing, cryogenics, aerospace, and particle physics industries where even infinitesimal porosity or leakage is intolerable. Learn more in our Bimetal Benefits PDF.

ATLAS BONDED MATERIAL PROCESSING

We achieve such high levels of performance through careful control of our processes from beginning to end.

- Pre-bonding materials certification

- Post-bonding ultrasound testing to identify non-bonded areas

- Dye-penetrant testing to assess porosity

- Manufacturing - cutting, welding, multi-axis machining

- Dimensional inspection during manufacture

- Helium leak check of all parts

- Final inspection before packaging

RECENT PROJECTS - ATLAS BONDED METALS

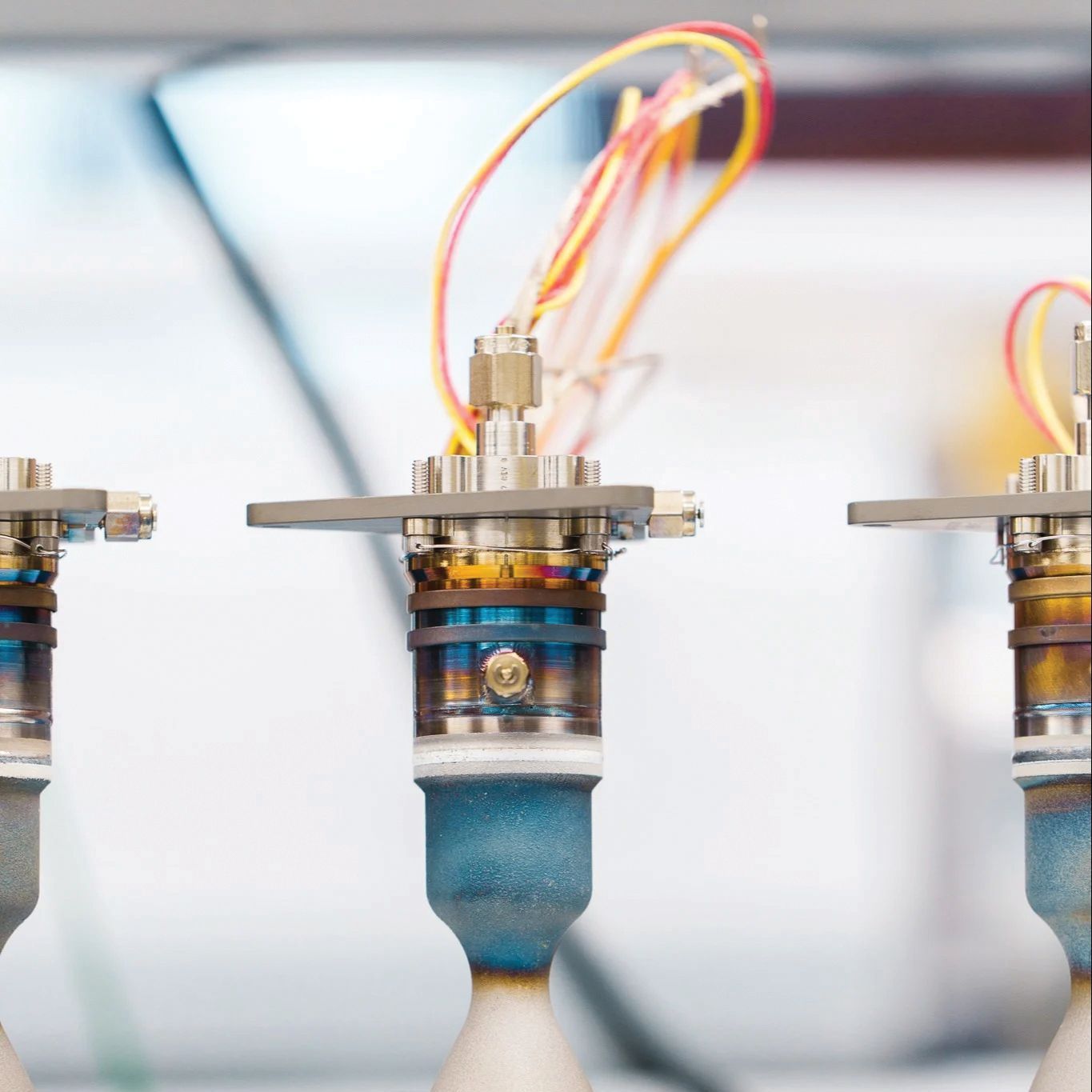

Niobium / stainless transitions used in rocket thrusters

In a recent project for Benchmark Space Systems, Atlas Technologies developed a niobium/stainless transition ring to connect the stainless-steel rocket thrusters head section to a niobium alloy nozzle. This bimetallic transition ring sits at a critical junction managing the 2000-degree temperature differential within a span of less than ½-inch.

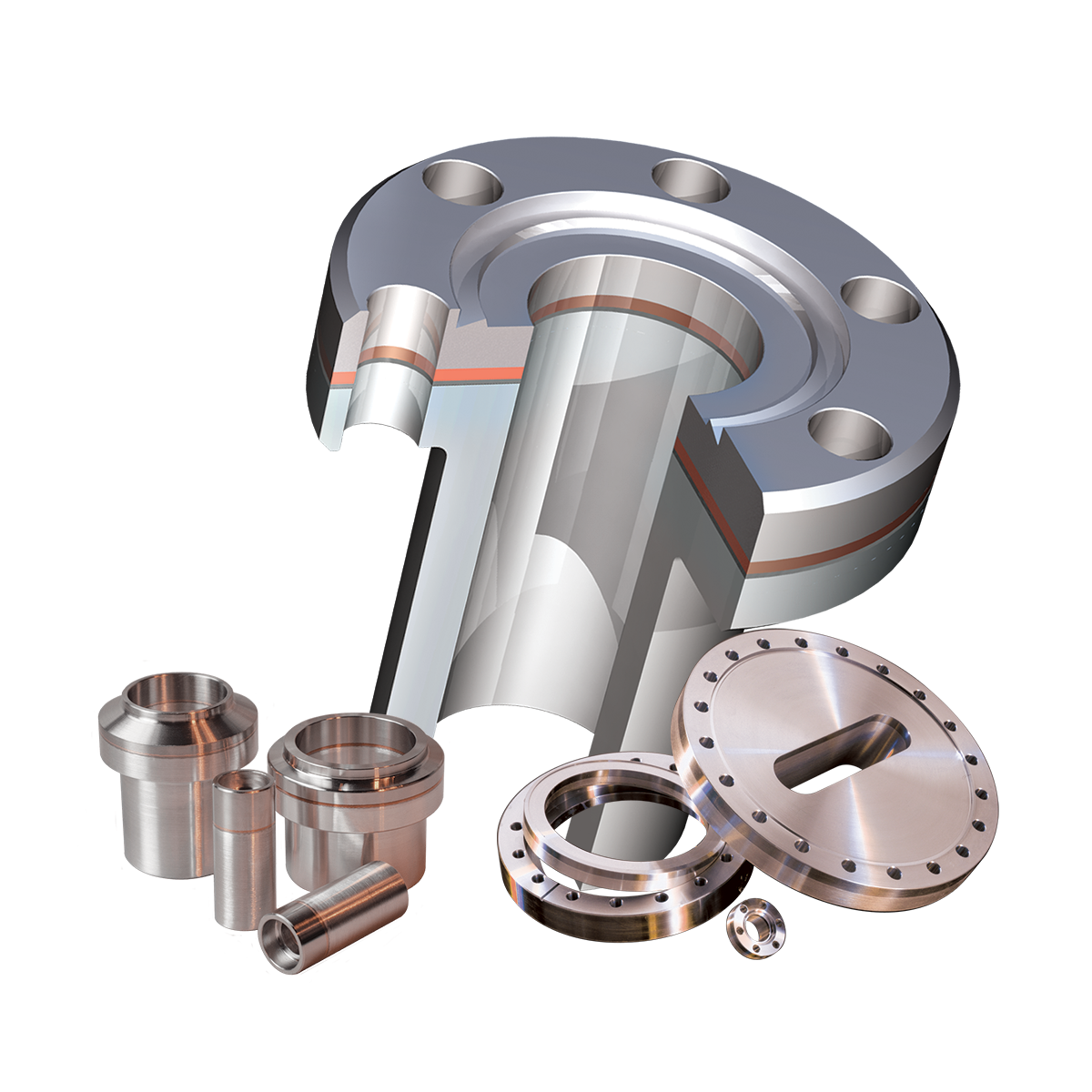

Aluminum / stainless chambers and fittings used in crystal manufacturing

High performance vacuum chambers are critical in the production of industrial crystals. Atlas aluminum chambers with bimetal fittings meet the needs of our customers in the diamond and crystal manufacturing industries. This Atlas chamber features bonded aluminum and stainless precision machined, then welded to multiple flanges and fittings.

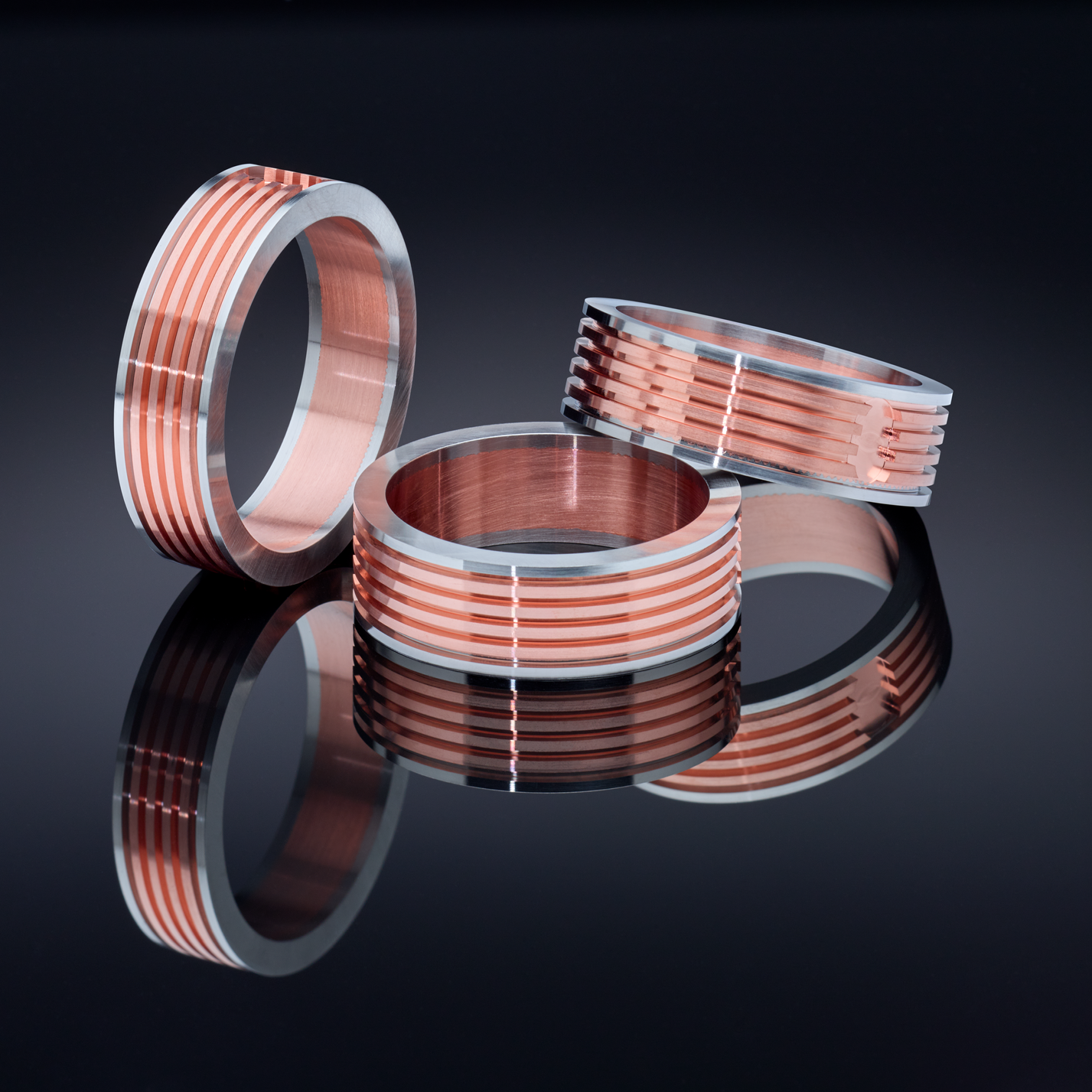

Copper / stainless transition used in cryogenics

Our customer came to us with a drawing and a request; could we make them a specialized fitting that sandwiched copper within layers of stainless steel for their cooling system. The answer? Yes, of course.

HOW CAN WE Help with your next bimetal project?

Designing a new aluminum vacuum chamber with bimetal aluminum/stainless flanges? Looking for custom titanium fittings for research or aerospace? Need a handful of our US-manufactured bimetal products and wondering which solution will work best? We can help.