PRODUCT DEVELOPMENT

BETTER Engineering. Better PERFORMANCE.

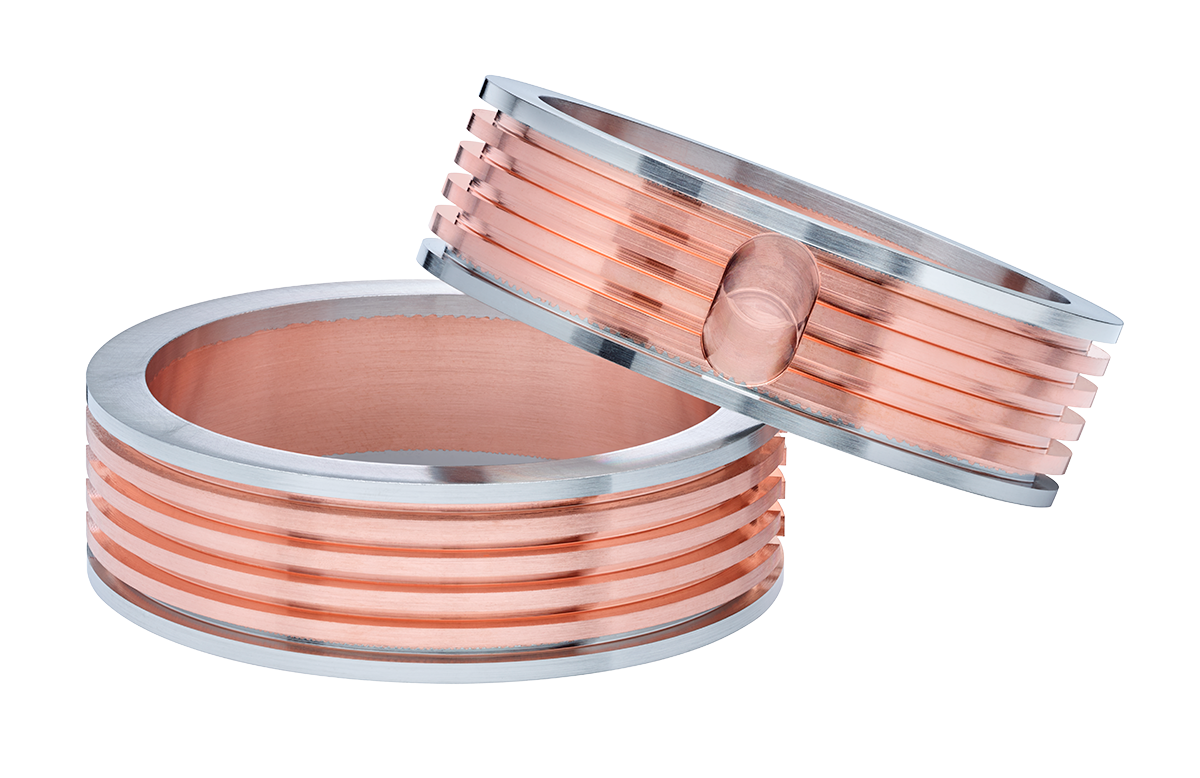

Working in bimetal and ultra-high vacuum, we have no shortage of interesting and challenging projects to work on. From a tiny niobium-stainless fitting capable of withstanding extreme heat in rocket thrusters, to a copper-stainless water jacket used in cryogenic temperatures, to aluminum and titanium vacuum chambers fitted with aluminum-stainless flanges, we’ve built it all.

Bring us your next project

Our customers come to us with all manner of projects. Sometimes they just bring ideas. Other times, it's a fully optimized design. Either way, we can help. From napkin sketch to fully developed design, through machining, welding, testing, assembly and beyond, we’re here for you.

We can

- Help you choose metals to manage weight, costs, temperature extremes, and other parameters

- Work through design challenges

- Translate existing designs to improve production

- Ensure manufacturability

Our inhouse engineering team will work with you to develop your component, vacuum chamber or system and ensure ease of manufacturing, resulting in a final solution that best fits your needs.

Bimetal Component Design & Engineering

It’s true that Atlas is known for developing aluminum and titanium vacuum chambers. As a result of all that experience, we’ve also become experts at bimetal component design as well. For many customers, our standard bimetal flanges and fittings do the trick. But we are often called upon to create something more unique.

Recent projects include:

- Niobium-stainless fittings for aerospace

- Copper-stainless water jackets for cryogenics

- Aluminum-titanium transitions for research

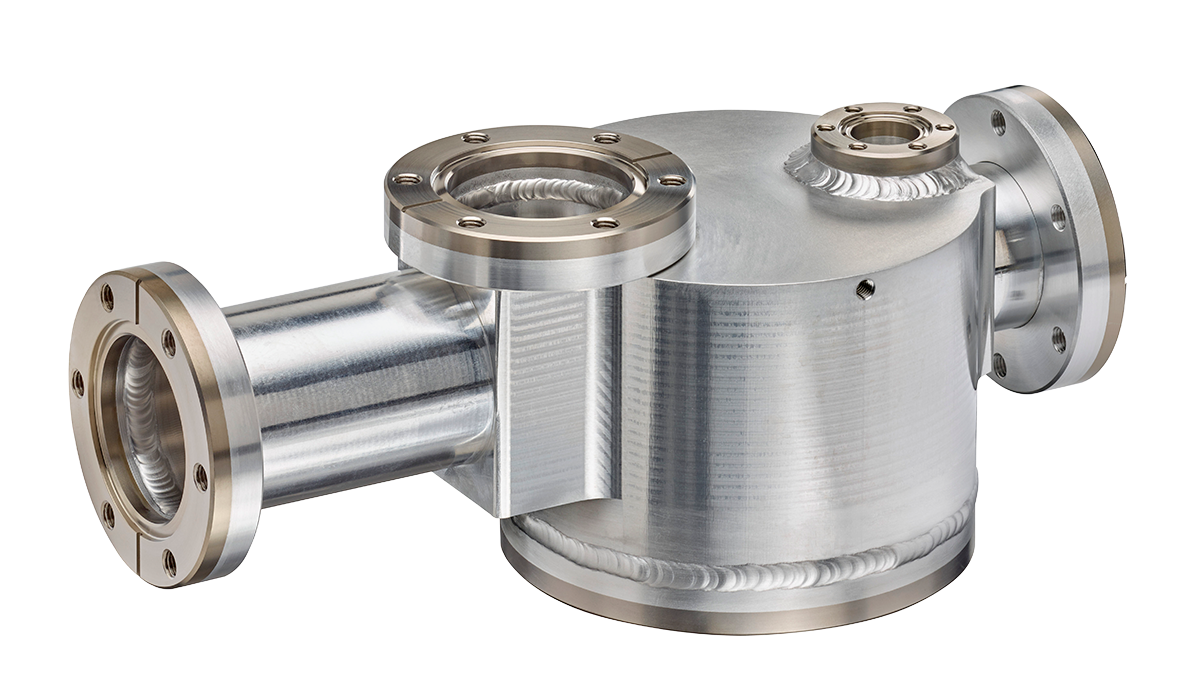

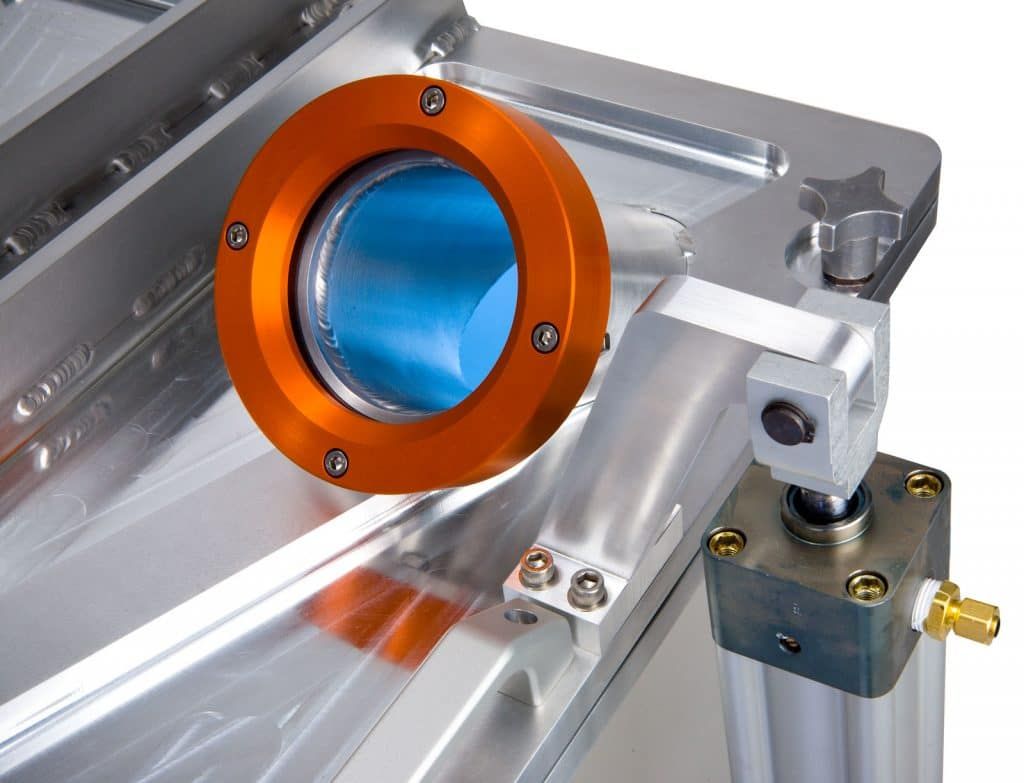

Vacuum Design & Engineering

Vacuum design has its subtleties. Material choices, geometry, pumping methods, pump access, weld locations, gasketing, and flanging all affect the cost and quality of your vacuum. With Atlas' vacuum design and engineering expertise, we can help you make the best choices to efficiently balance these factors and get you the vacuum performance you are looking for.

The design of your vacuum system will have a huge impact on its performance. A good design will get you the performance you require (base pressure, pump-down speed, etc.) without excessive pumping costs.

We’ve seen many instances where people add bigger pumps to their vacuum systems in an attempt to reach a desired base pressure, when a better vacuum system design can achieve the same goal. This energy-intensive approach ends up being significantly more expensive.

For UHV and XHV, poor vacuum design can make it impossible to reach base pressure goals no matter the pumping method. We are happy to help.

Our extensive experience with vacuum systems and a range of materials allows us to reach your goals more efficiently. Many of the chambers and products we produce are significantly redesigned or modified by Atlas to enhance manufacturability or improve vacuum performance.

Let us know how we can help.

ATLAS VACUUM CHAMBERS AND BIMETAL FITTINGS ARE USED IN:

- Chemical and physical vapor deposition (CVD/PVD)

- Semiconductor manufacturing, processing and movement

- Particle accelerators and physics research

- Aerospace - space inflight, testing and research

- Quantum computing enclosures and cryogenics

- Emerging energy technologies and processes

HOW CAN WE ASSIST IN YOUR PRODUCT DEVELOPMENT NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a rough sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.