UHV AND XHV INGENUITY

UHV and XHV are quite a bit different than the lower vacuum regimes. Vacuum chamber material, chamber geometry, pumping methods, and conductance all play a huge role in the quality of the vacuum.

The gases inside an XHV vessel can behave counter-intuitively. In XHV for example, gases will appear to collect in a certain section of vessel as if to create a localized high pressure zone. However, this is the wrong way to think about what is actually happening. From a problem solving standpoint, it is better to visualize this as a lower vacuum zone where there is a conductance limitation. This limitation confines gases so they collect in particular geometries.

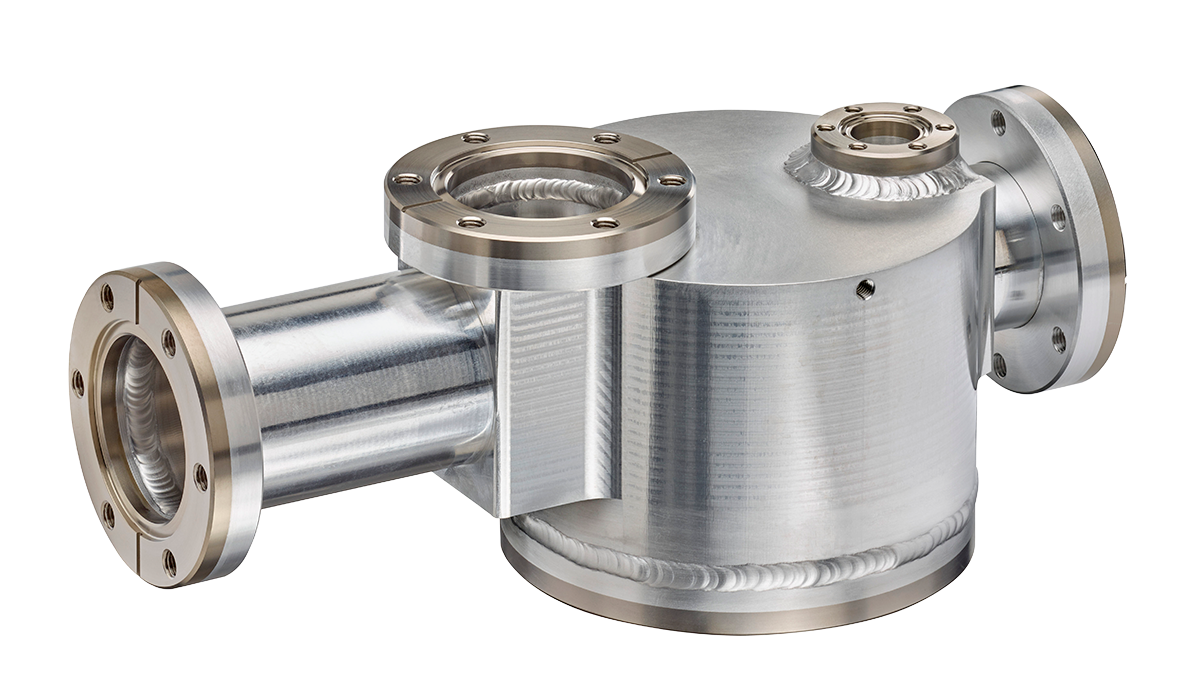

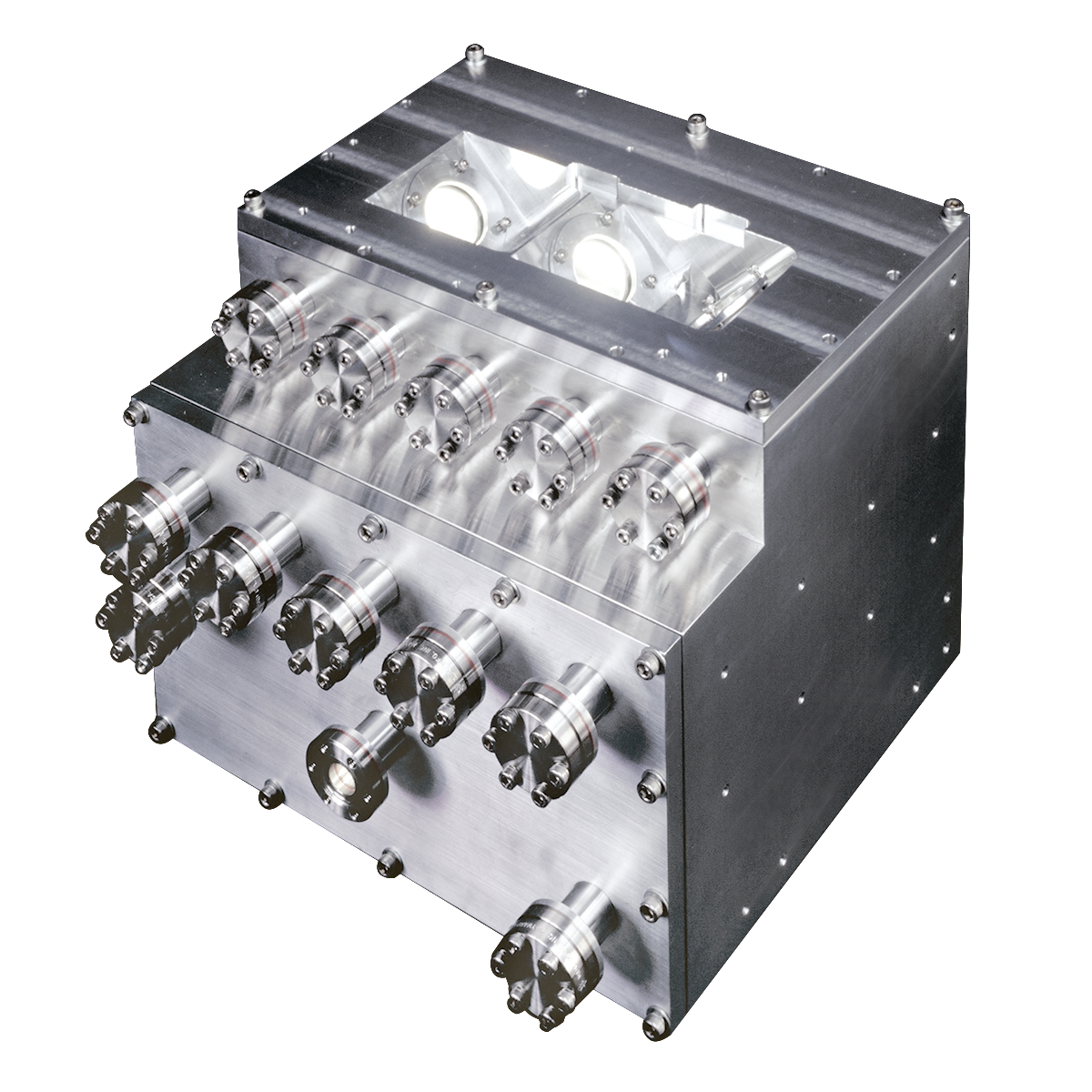

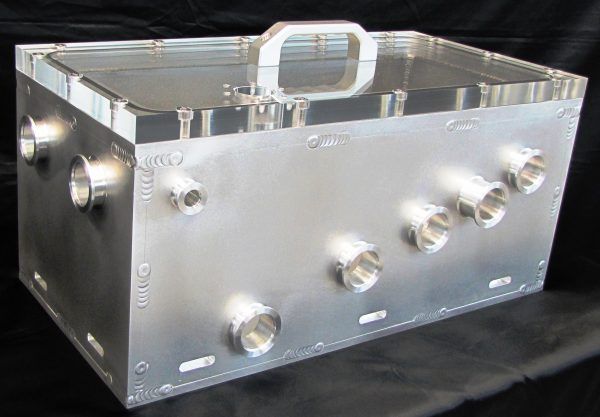

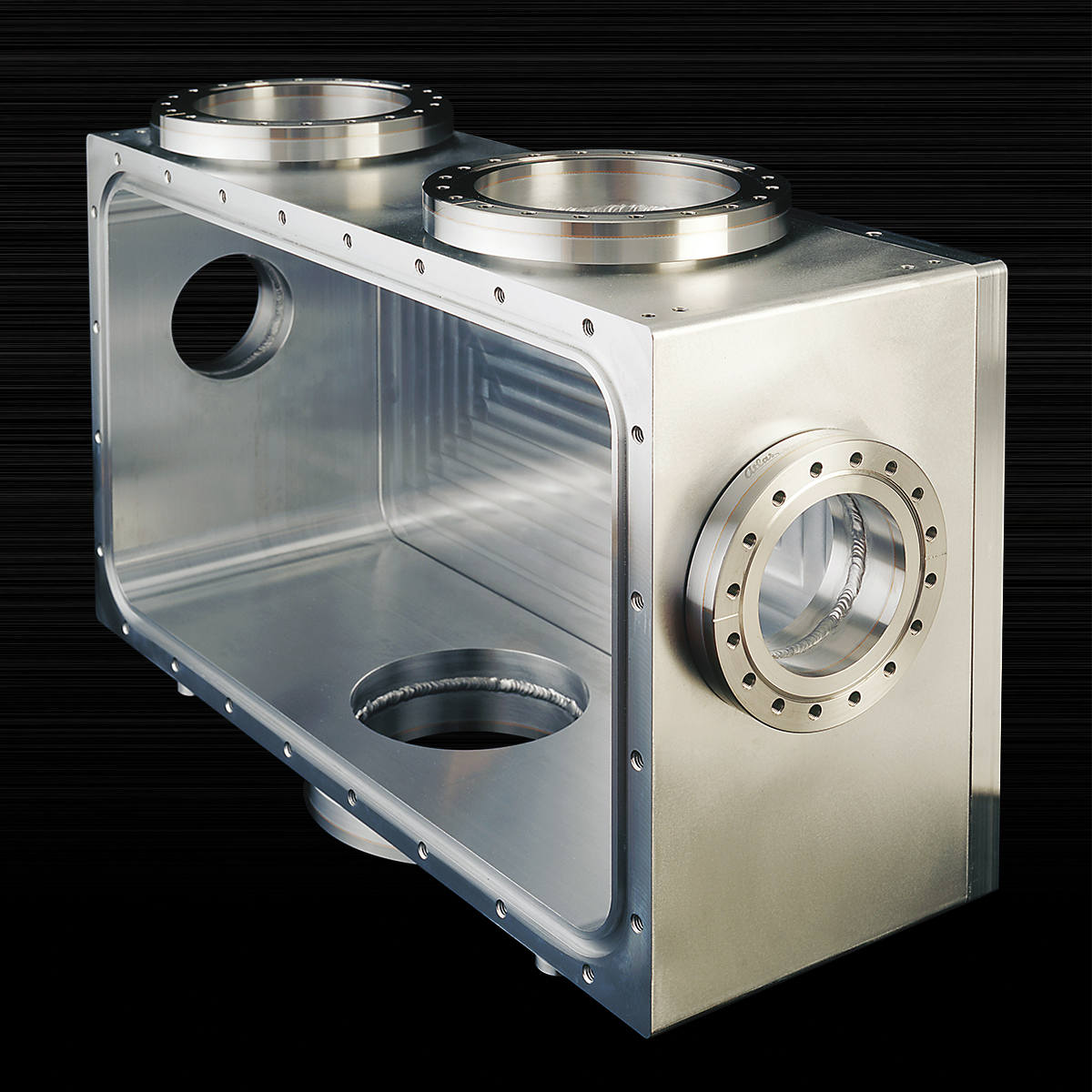

We have designed and built a wide variety of UHV and XHV vessels for many different applications ranging from industrial OEMs to national laboratories and universities. We have experience in integrating non-evaporative getter pumping (NEG) with titanium sublimation pumping (TSP) directly into the vacuum vessel so that extremely high vacuum levels can be achieved.

KEY DESIGN POINTS FOR UHV AND XHV

It is very important to utilize materials with low hydrogen permeability and desorption rate.

Stainless steel is not a good choice because of its very high solubility and substantial hydrogen content. Aluminum is a great cost-effective option, while titanium is a superb, high-performance choice, particularly if you need to bake-out at a very high temperature.

Pumping is very important.

Pump types include scroll, turbo, ion, TSP, and NEG. There are newer, specialized turbo pumps that can approach XHV pressures, provided they are combined with excellent backing pumps.

Designing systems with the proper conductance is critical to achieving UHV and XHV levels.

The mean free path of gases (the distance a gas molecule will travel before hitting another) are extremely long, which means that conductance becomes very important. Large, unobstructed pumping ports are essential, because confined geometries may collect gas.

We offer UHV and XHV engineering and design services.

Our knowledge and expertise with material options beyond stainless steel equips us to properly design your UHV and XHV vessels. We understand the importance of a manufacturable design, and with our fully equipped machine shop, we can make your design a reality. We look forward to talking with you!

HOW CAN WE ASSIST IN YOUR UHV AND XHV INGENUITY NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a simple sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.