AEROSPACE

Atlas bimetal solutions take to the skies

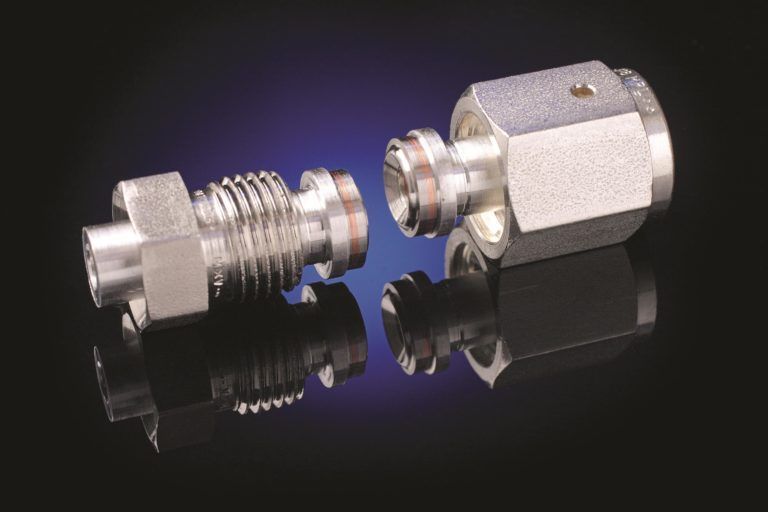

Atlas hermetically bonded solutions combine the advantages of two or more metals – such as the heat capacity of niobium with the lower costs of aluminum or stainless – to make robust, long-lasting connections. Lightweight aluminum and titanium solve myriad aerospace challenges.

Relentless performance where it’s needed most

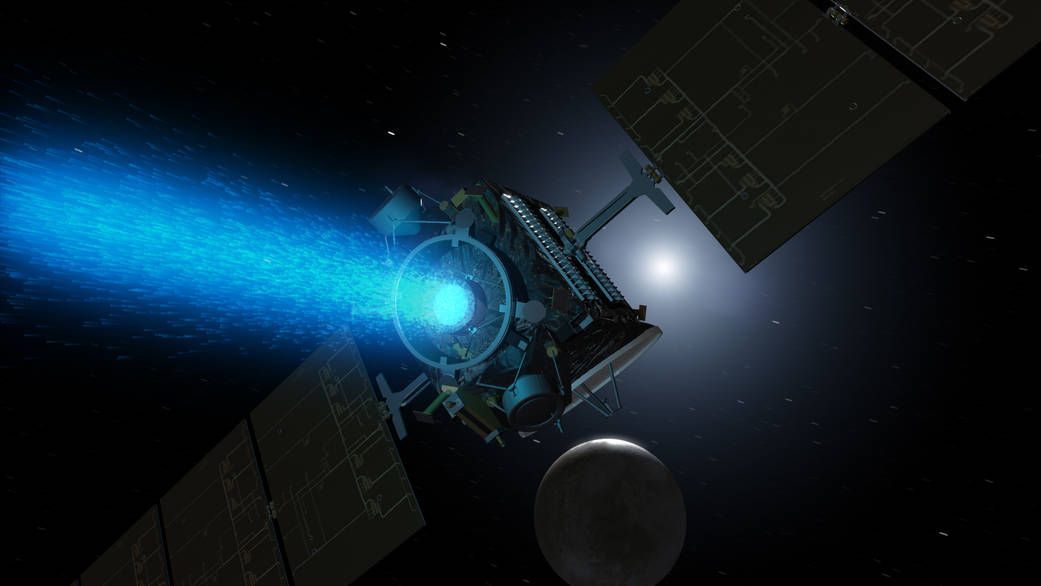

Atlas bimetal components are found in lunar landers, rocket thrusters, and satellites. NASA JPL, Blue Origin, SpaceX and various national labs working in aerospace and defense come to us for help designing and manufacturing complex products that need to perform relentlessly in the most demanding environments.

In a recent project for Benchmark Space Systems, Atlas Technologies manufactured niobium/stainless transition rings to connect stainless-steel rocket thruster heads to niobium alloy nozzles. These bimetallic transition rings sit at a critical junction in the system, managing the 2000-degree temperature differential within a span of less than ½ inch.

Recent Atlas aerospace projects include:

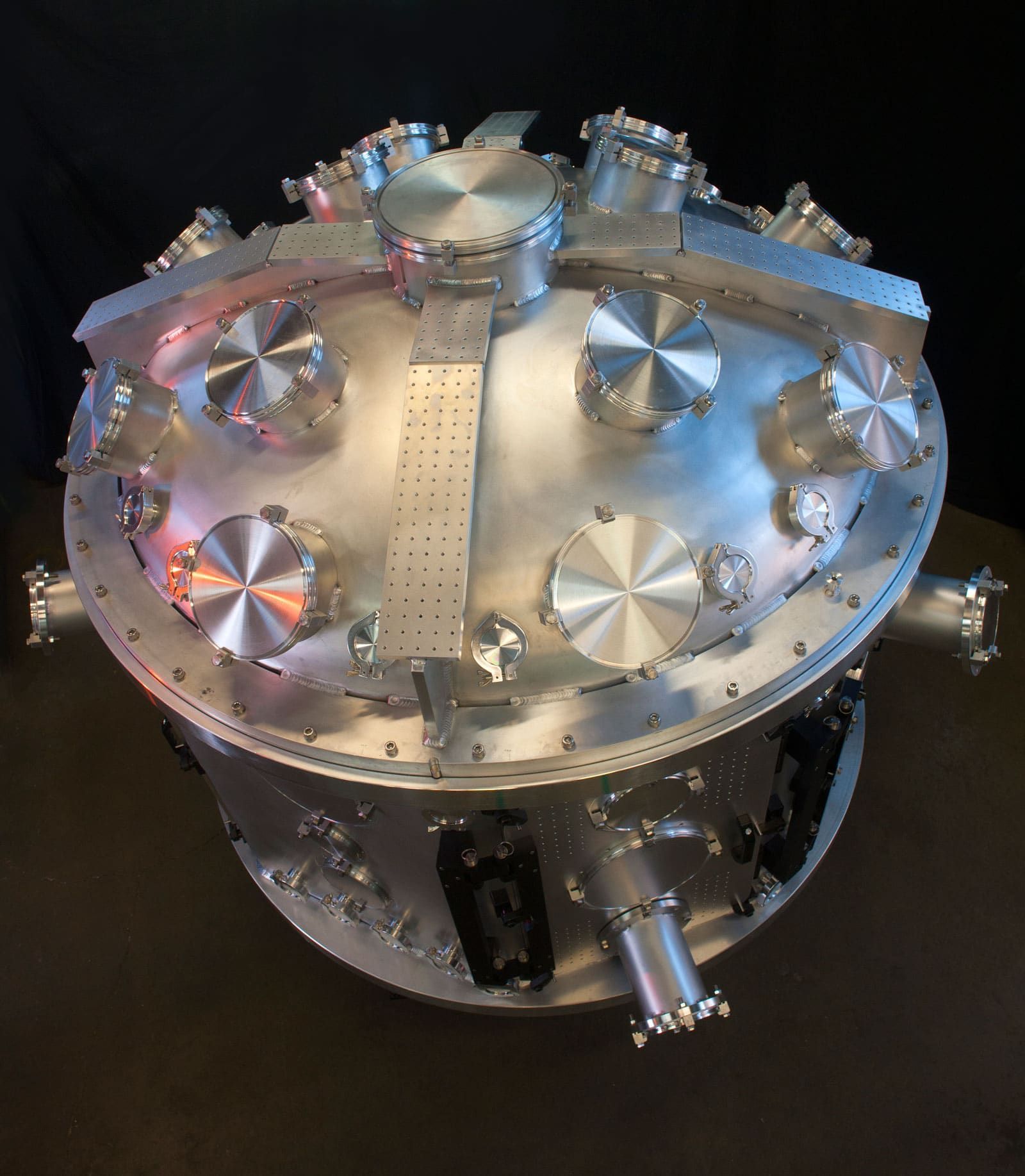

- Atmospheric and space simulation chambers

- Commercial and government satellites

- Moon landers

- Gravitometers

- Rocket thrusters

From common to complex, we can help

We regularly bond and machine aluminum, titanium, niobium, copper, and stainless steel in our fully integrated facility located in United States, and we happily help customers with other metals as needed.

Custom and standard solutions are available.

Come talk to us about your next engineering challenge.

HOW CAN WE ASSIST IN YOUR NEEDS?

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a simple sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.