A bit about how bimetallic bonding works

Now in our third decade, Atlas Technologies continues to develop methods and processes to effectively bond dissimilar metals for use in Ultrahigh Vacuum (UHV) as well as other demanding applications. While the details are proprietary, you can get a working understanding of the process below.

Metallurgical Bonds

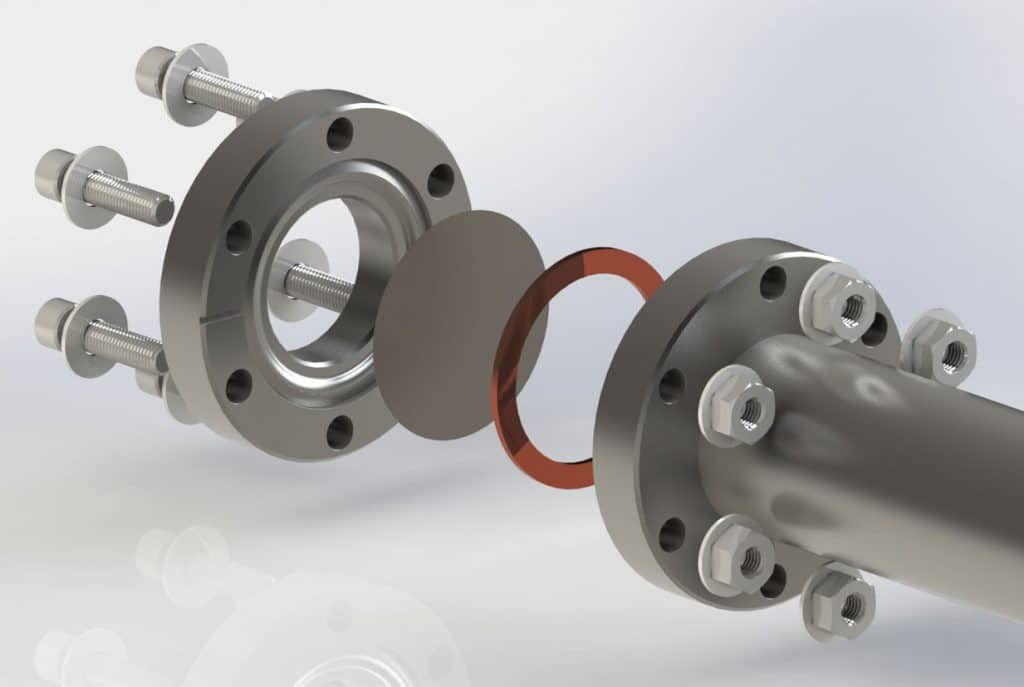

Atlas bimetallic flanges and fittings are constructed of metallurgically bonded plates created through our proprietary bonding process. To form the bonded metals, a flyer plate sits atop a base plate separated by a small gap. An explosive material, such as ammonium nitrate, is placed on top of the flyer plate and detonated from a point at one edge of the plate. The explosion is a controlled progressive ignition starting from one point on the surface of the flyer plate and progressing across it, like the ripples on a pond created from the drop of a rock.

The energy from the explosion accelerates the flyer plate against the base plate at impact velocities of 1800-2200 m/sec. A high energy surface plasma is formed between the plates, which moves ahead of the collision point stripping electrons from the two bonding surfaces. The electron hungry metals are then thrust against each other at extreme pressures forming an electron sharing bond.

Bonding Parameters

Atlas bonds several different metals but concentrates primarily on metals needed for UHV applications. The formation of multi-laminates by explosive bonding involves deep knowledge of the process variables and the ability to control them. The critical bonding parameters include explosive detonation velocity, explosive load, and interface spacing. The metallurgy of the dissimilar metals at the bond interface is an additional consideration. Imagine the constituent metals acting as a viscous fluid in the reaction zone (bond-line interface).

The key bonding parameters along with careful preparation of metals to be bonded results in a successful bonding event. Through the precise control of bonding parameters, interface turbulence is also controlled. An ultrahigh vacuum interface requires that a smooth flowing wave pattern be developed. Excessive turbulence may result in leak paths and possibilities.

Multi-layer Composites

Metals such as copper and stainless are readily bondable. However other metals such as aluminum and stainless are incompatible if bonded directly to each other. Many materials are not directly bondable without the formation of brittle intermetallic compounds. Atlas has developed patented multilayer composite technologies to facilitate metallurgical compatibility between aluminum, stainless and other metals. Multi-layer composites also provide diffusion barriers to eliminate formation of the brittle intermetallic compounds during weld up or through repeated heat cycles such as bakeout and high heat processes. Titanium and copper are the typical materials used to achieve diffusion protection for aluminum/stainless flanges.

The time duration of the explosion welding event is small and the heated reaction zone between the metals microscopic. The remaining thickness of the metal remains near ambient temperature and acts as a heat sink to the reaction zone. Therefore, the bond-line is an abrupt transition between the metals with little, if any, degradation of the metals. This process allows Atlas to produce stainless/aluminum and stainless/copper flanges while retaining a T-6 temper in the aluminum and, in the case of copper, maintaining a half hard RF78 condition. Other processes would anneal these materials leaving them too soft for many UHV applications.

On close examination you will notice a wave pattern at the bond line. The pattern is more noticeable depending upon whether you are observing a crossing section or parallel section. The pattern develops in the bonding process as the flyer plate is accelerated against the base plate. The wave pattern increases the mechanical strength of the bond - in shear by offering mechanical interference and in tension by offering more bonded surface area. All materials used are UHV compatible and are metallurgically bonded using this solid state process. No adhesives are used.

Bond-Line Wander

The explosion bonding process is extreme, leaving the bonded plate with obvious extrusions, deformations and warpages. Atlas takes great care to flatten the plate after bonding. And as each flange is produced, careful attention is given to positioning the bond line – typically to ±0.04” variance and as small as ±0.012”. However, when carefully comparing one flange to another, you will observe that even though the flanges are dimensionally alike, no two flanges exhibit the same bond line location. Bond line wander does not affect the mechanical integrity or the function of the flange for UHV application.

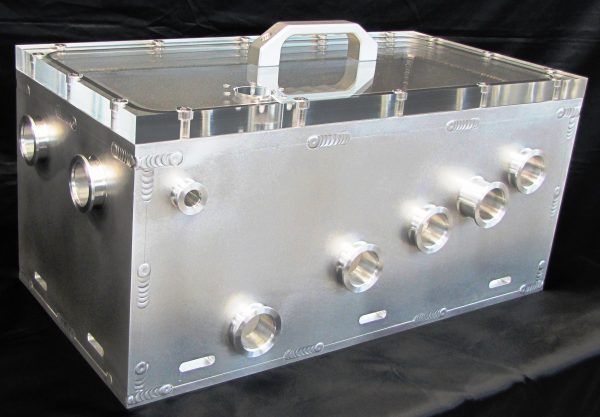

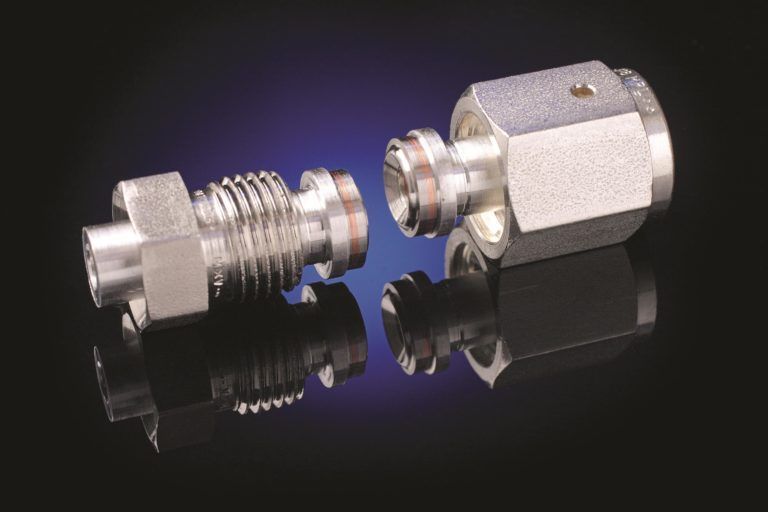

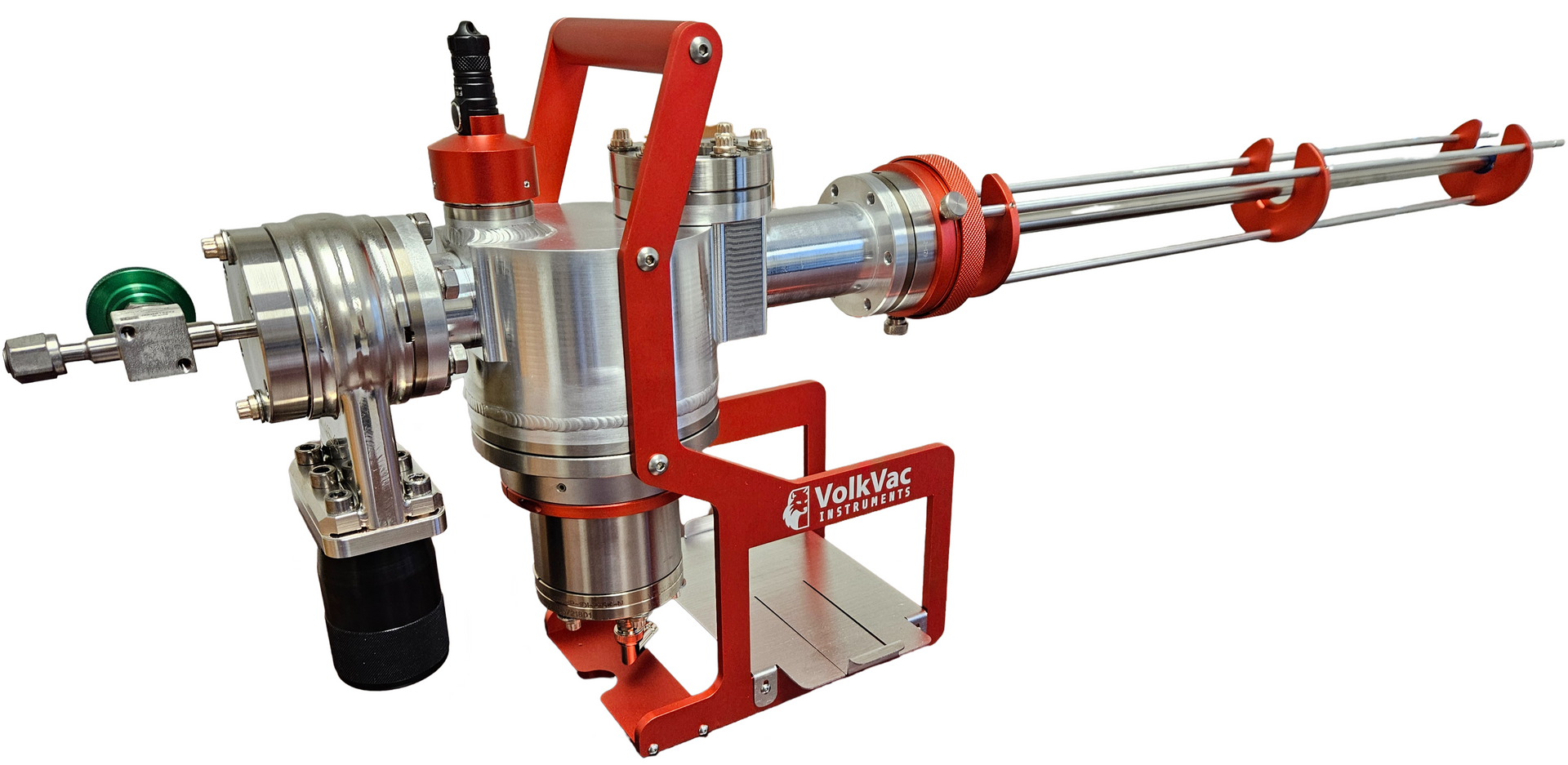

UHV Metal Bonding Capability

The explosive bonding process has been used as an industrial process for over 40 years. However, the industrial applications for large heat exchanges and for ship building are not suited for UHV where bonds must operate at leak rates less than 1×10-9 to 1×10-12 Torr. Atlas Technologies has developed UHV bonding processes for a group of metals commonly used in UHV applications. Although our CF flanges and ATCR fittings are most commonly used, we have also developed successful bonding architectures and metal combinations suitable for use in semiconductor, particle physics, cryogenic, aerospace and other demanding applications.