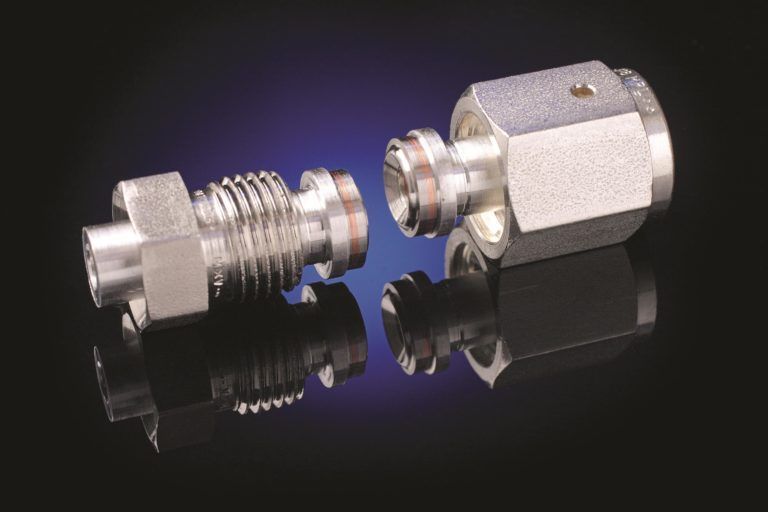

Atlas Technologies builds a non magnetic model of its Atlas FlangeTM, the aluminum flange with a stainless steel knife-edge and face using 316LN stainless. This alloy ensures a minimal magnetic permeability from the stainless steel while providing an aluminum base for weld-up to an aluminum chamber that is not magnetized during welding. The magnetic permeability of aluminum, near unity, and its excellent vacuum properties such as extremely high thermal conductivity, low H2 and no C content, light weight and low Z make aluminum a superior vacuum material for many UHV applications. See our section on aluminum vacuum properties for more information.

Atlas also manufactures Atlas Flanges with hardened knife edges and faces using materials other than stainless. For example Atlas uses titanium instead of stainless as a knife edge material. This reduces the magnetic permeability even more than using 316LN and is ideal for extremely magnetically sensitive applications.

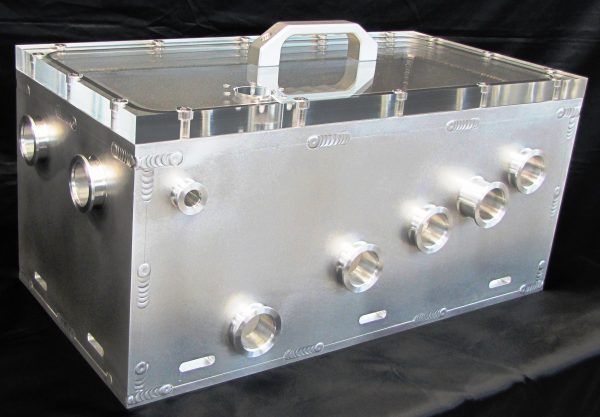

Some non magnetic applications are better served with copper Ultra High Vacuum UHV chambers and flanges. Atlas manufactures custom copper chambers with hardened flanges surfaces to meet your specifications.

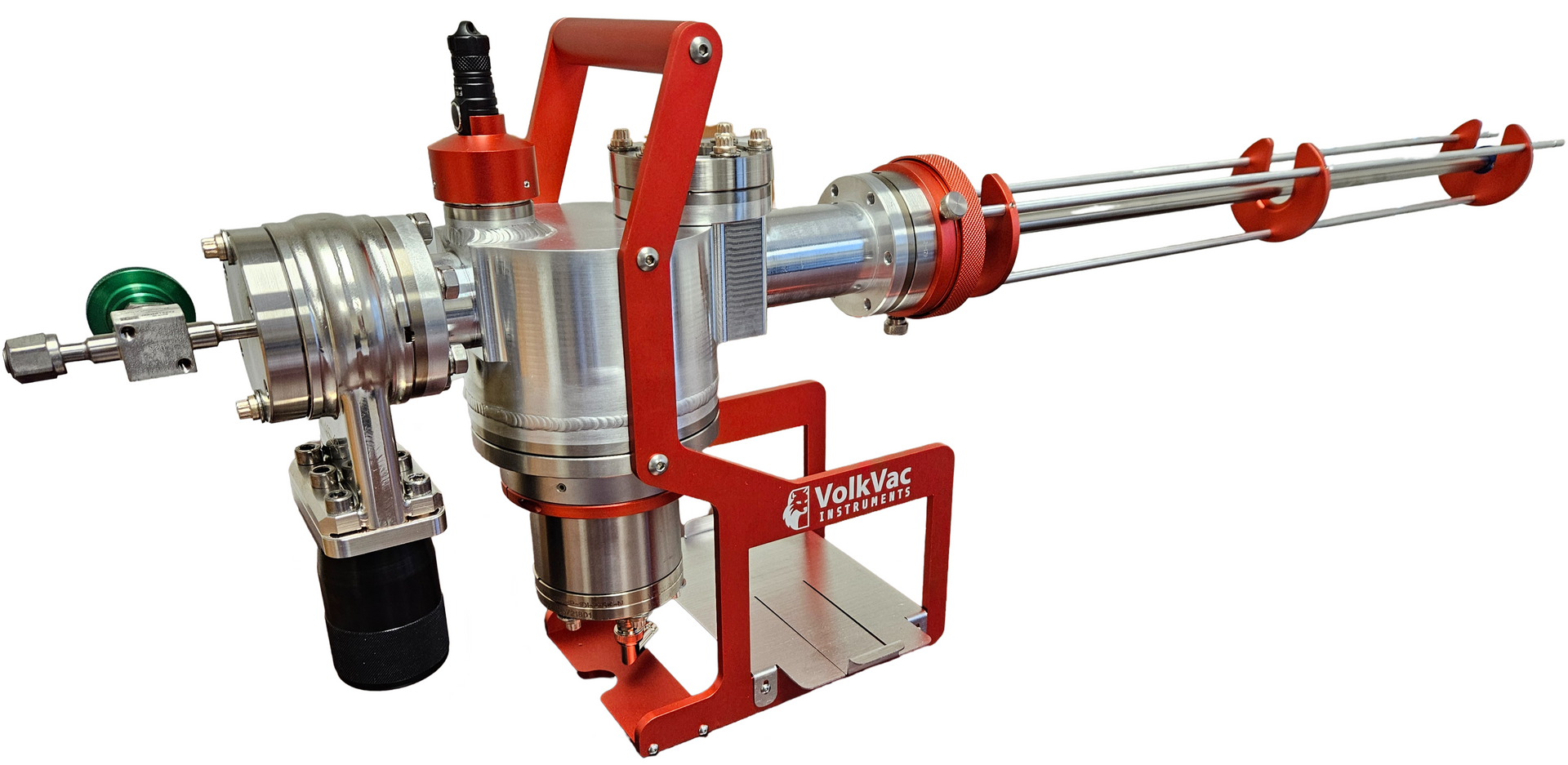

Low permeability Atlas CF Flanges and chambers are in use at prominent national lab and accelerator facilities world wide. We would be delighted to talk with you about your application and assist you in the engineering and manufacture of flanges or chambers.

Atlas Technologies offers low magnetic permeability stainless steel Ultra High Vacuum Atlas Flanges. These flanges enable you to apply the excellent extremely low permeability of aluminum through-out your vacuum system and still enjoy rugged stainless knifes with magnetic permeabilities far below conventional stainless steel.

The low mu Atlas Flanges are carefully manufactured with atlas’ proprietary technologies yielding a very low permeability in the stainless around ~1.017 µ.

Because aluminum has a lower mu than the low mu stainless and is less expensive, Atlas’ low mu flanges are the clear choice for low permeability vacuum applications.

Atlas stocks low mu Atlas flanges:

| Name | Composition | Permeability | Permeability | Coercivity | Retentivity | B max | Resistivity |

|---|---|---|---|---|---|---|---|

| **, *** | Initial | Max | He (Oe) | Br (G) | (G) | ||

| Al Pure | 1.00002 relative | – | |||||

| Iron Fe | Annealed (pure) | 25,000 | 3,500,000 | 0.05 | 12,000 | 14,000 | 9.7 |

| Cast Fe | 100 | 600 | 4.5 | 5,300 | 20,000 | 30 | |

| Rhometal | 36 Ni, Bal. Fe | 1,000 | 5,000 | 0.5 | 3,600 | 10,000 | 90 |

| Permalloy 45 | 45 Ni bal Fe | 2,500 | 25,000 | 0.3 | 16,000 | 45 | |

| Mu Metal | 71-78 Ni 4-6Cu 0-2Cr bal Fe | 20,000 | 100,000 | 0.05 | 6,000 | 7,200 | 25-50 |

| Supermalloy | 79 Ni 5 Mo balFe | 100,000 | 1,000,000 | 0.002 | 8,000 | 60 | |

| HyMu80 | 80 Ni bal Fe | 20,000 | 100,000 | 0.05 | 8,700 | 57 | |

| Sendust | 10 Si, 5 Al, bal Fe | 30,000 | 120,000 | 0.05 | 5,000 | 10,000 | 60-80 |

| Alfenol | 16 Al, bal Fe | 3,450 | 116,000 | 0.025 | 3,800 | 7,825 | 150 |

Relative Permeability (µr) refers to the ratio of magnetic flux in any element of a medium to the flux that would exist if that element were replaced with air, magnetic-o-motive force (mmf) acting on the element remain unchanged (µ r = µ/µ 0)*

Permeability (µ) is the ratio unit magnetic flux density to unit magnetic field intensity in air (B/H) the Permeability of air is 1.257 x 10 6 henry per metere*

*Marks standard handbook for mechanical engineers, 9th edition (ISBN 0-07-004127-X)

** A Physicist’s Desk Reference Second Ed. (ISBN0-88318-610 (pbk))

*** Electronic Properties of Materials (ISBN 0-412-49590-2)