oUR Processes

Our customers count on us to design, develop, manufacture and support a broad range of aluminum, titanium and bimetal solutions. From initial input to fully developed design, through machining, welding, testing, assembly and beyond, we’re here for you.

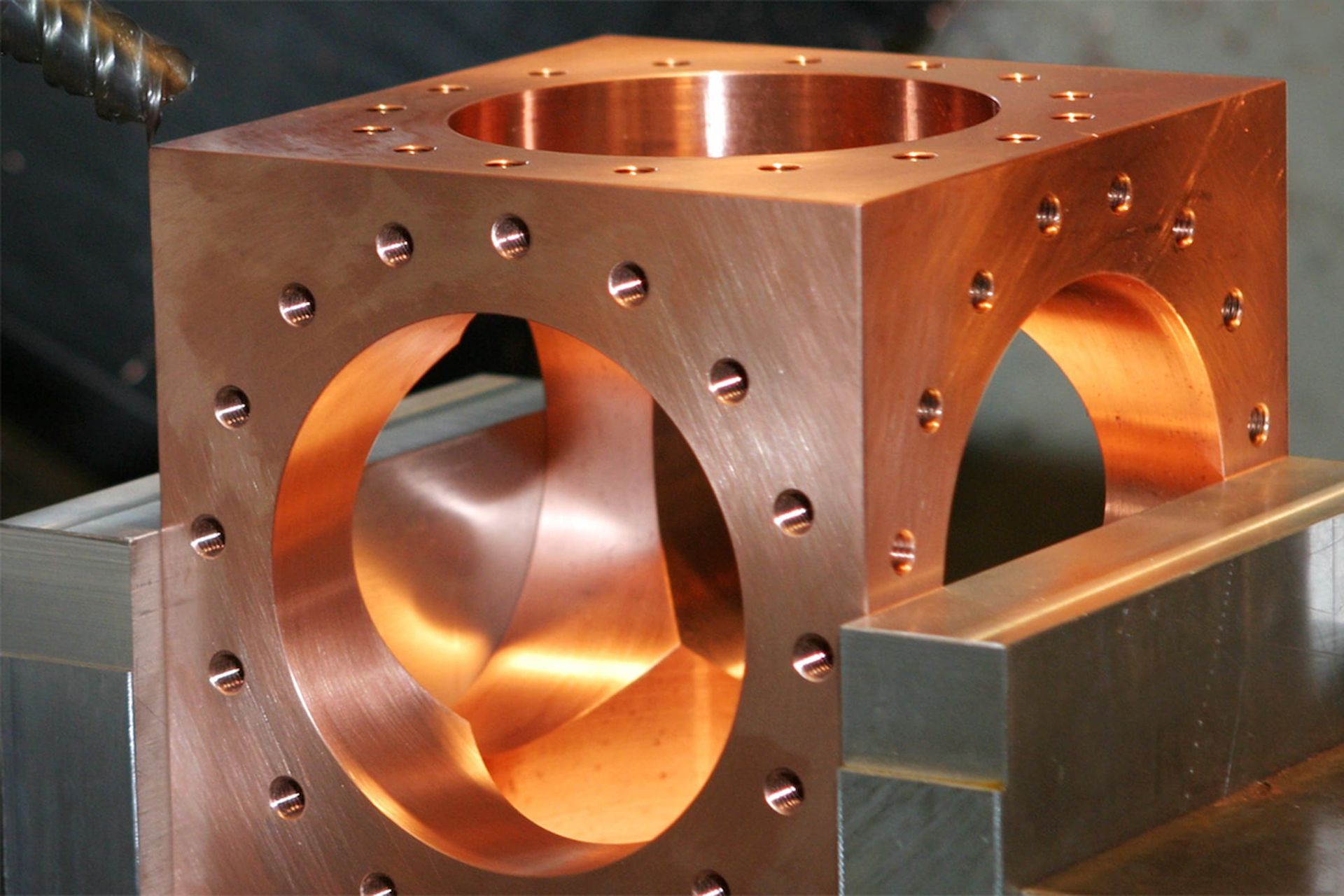

For bimetal products, we begin with the best quality metal plates available. Each plate is bonded using proprietary processes. Plates are then fully tested to ensure a solid metallurgical bond. Components are then cut from the bonded plate and machined.

All-titanium, all-aluminum and a broad range of bimetal fittings and flanges are available as standard and custom solutions.

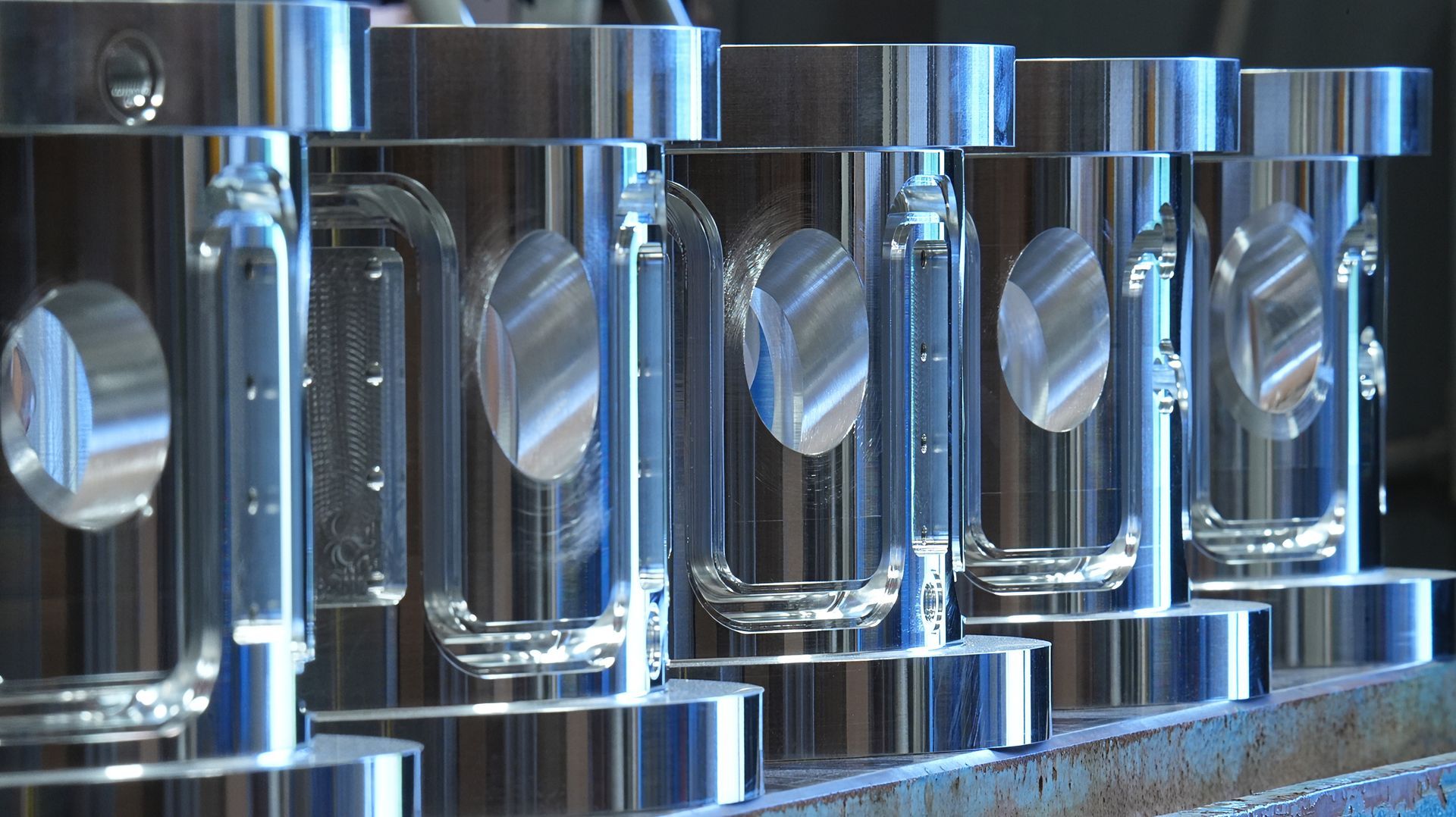

Vacuum chambers are machined in either aluminum or titanium and then joined with appropriate bimetal flanges or fittings to support customer needs.

Design

We've had the pleasure of designing components and chambers used in space missions, particle colliders, fusion energy experiments, and quantum computing, as well as simpler everyday applications. Our onsite, in-house engineering team works closely with customers to bring their ideas to fruition, and improve functionality, performance and manufacturability.

- New requests are submitted via our website, through email or in discussion

- Sales and engineering work together to determine lead times and best approaches to ensure the desired functionality.

- Designs and drawings are finalized and approved with the customer.

- If appropriate bonded materials are available, we move onto development and manufacturing. If not, we'll get the materials ready.

Development

Many of our customers come to us with fully fledged designs that require little, if any, iteration. Others come with early concepts and ask for help developing them further. This can involve:

- Functional assessment

- Testing of potential new metal combinations

- Review of metal thicknesses, radii, and other physical characteristics

- Destructive testing

- Manufacturability reviews

Manufacturing

Every project requires a slightly different approach, but all follow a similar progression.

- Bonding and testing the plates (for bimetal)

- Cutting materials (hog-out, individual plates, or blanks)

- Precision machining (multiple processes and passes as needed)

- Welding

- Testing

- Product cleaning and detailing

- Careful packaging and shipping

Support

As customers deploy their new vacuum chambers and components, we are available to help with any questions or necessary updates.

If products are used in destructive processes, we can often rebuild them.

We support customers in all industries including semiconductor, aerospace, quantum, and research.