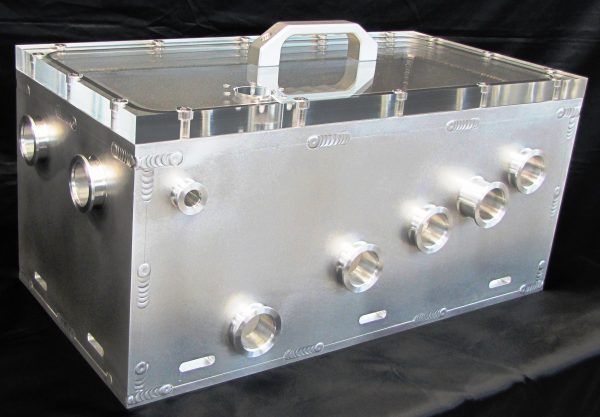

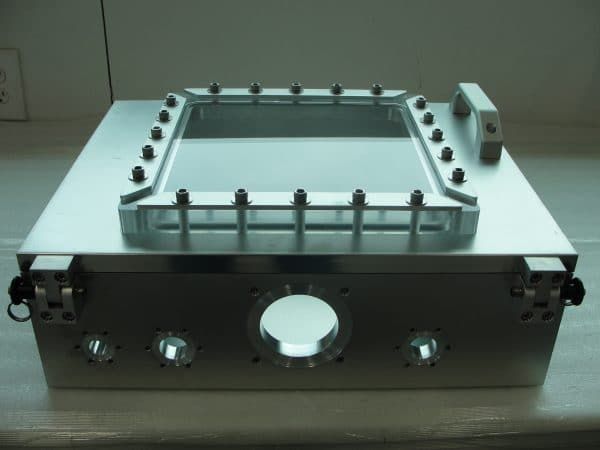

Denton Vacuum, a leading supplier of production scale thin film technology systems, has added a new Atlas manufactured Loadlock chamber to the Explorer Deposition System in its Customer Application Center (CADC).

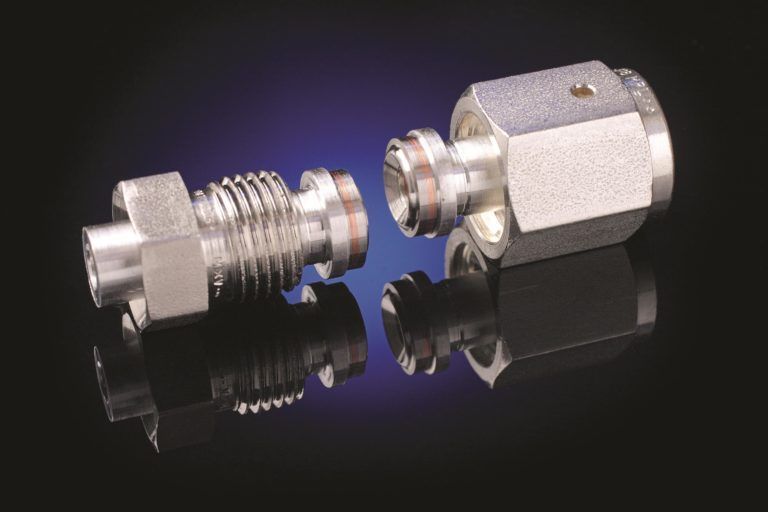

The loadlock chamber enables the loading and unloading of wafers in a much more efficient way: the semi-automatic feeding also allows the main processing chamber to remain at high vacuum while material is loaded and unloaded from the newly added subsystem.

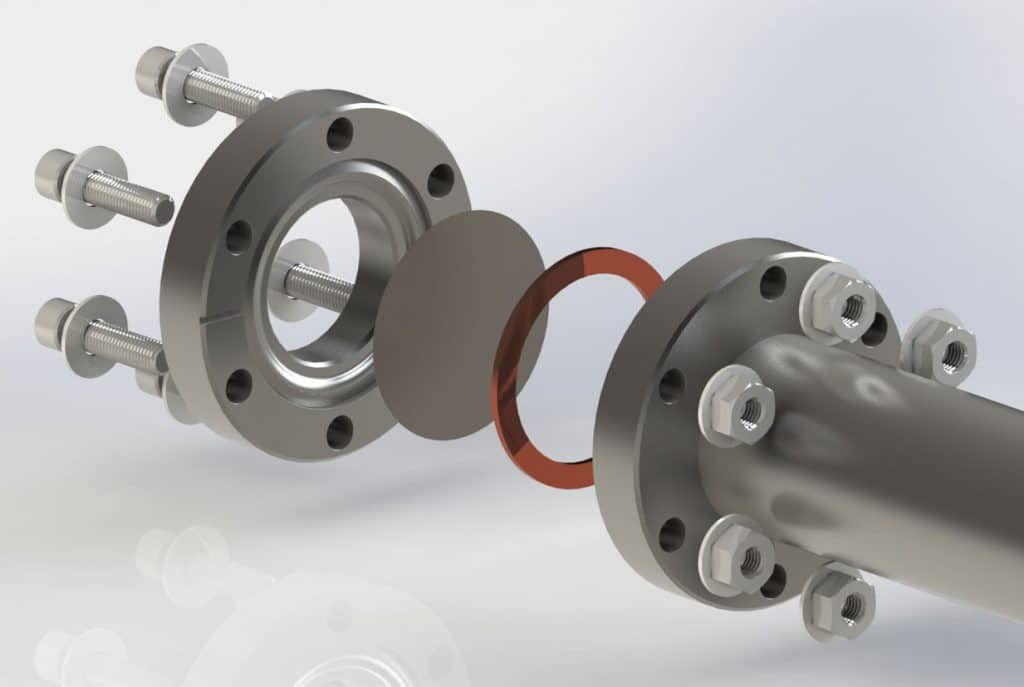

While the main process chamber remains at vacuum, the finished wafer is extracted from the chamber, a loadlock valve is closed and the chamber is returned to normal pressure. The wafer can them be replaced, the chamber pumped down and then the water placed inside the process chamber.

Savings as high as 90 minutes per cycle may be realized with the additional capability.

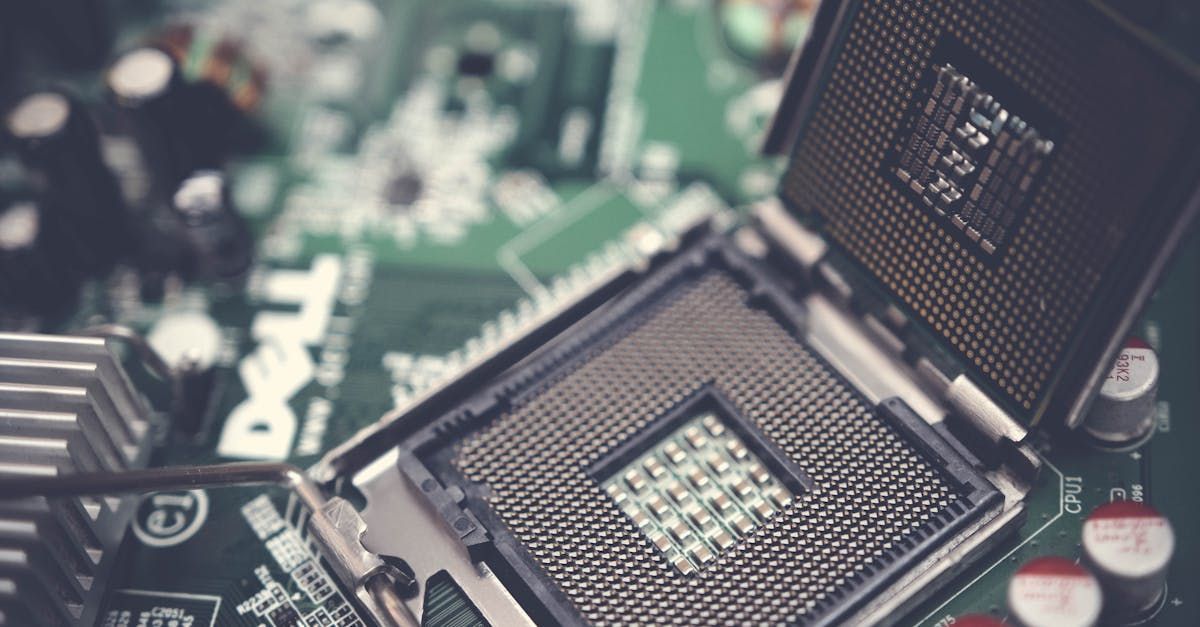

Dr. Craig Outten and his team are working on several groundbreaking processes at the CADC which include coatings for medical devices including Titanium Nitride fractal coatings, advanced sputtering of metals and dielectrics, optical coatings, atomic layer deposition, and coating macromolecules for TEM.

For projects like these, Atlas aluminum chambers advance the vacuum process with very low hydrogen, speedy pump down, lightweight and maneuverable equipment, and even bake out.