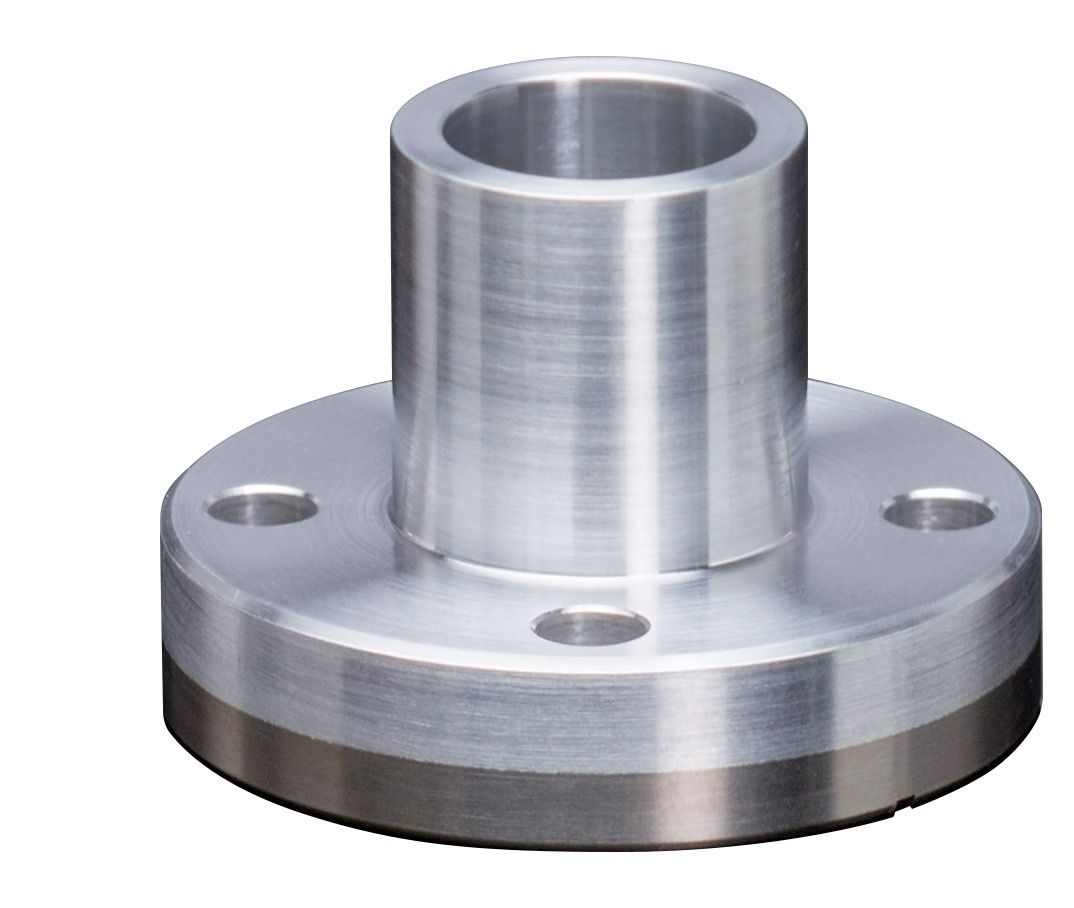

Bimetal Ti/Al CF Flanges

Durable, non-magnetic UHV sealing for aluminum vacuum chambers

Atlas Bimetal Ti/Al CF Flanges feature an aluminum flange body bonded to a rugged titanium face for a completely non-magnetic vacuum system.

Product Specifications

Titanium UHV Sealing for Aluminum Chambers

The Atlas Bimetal Ti/Al CF Flange with aluminum flange body bonded to rugged titanium uses the time-tested reliability of the ConFlat® (CF) knife-edge seal. After welding the CFTA™ flange to an aluminum vacuum chamber, it becomes a completely non-magnetic UHV chamber. This supports applications where high magnetic permeability is detrimental to beam quality or experimental results.

Non-magnetic aluminum vacuum chambers are used for UHV synchrotron, particle physics, and industrial applications where high magnetic permeability is detrimental to beam quality or experimental results. Such applications include non-magnetic beam tubes, wigglers, undulators, free electron lasers (FEL), drift tubes, and spectrometers.

Applications:

- UHV synchrotron

- Particle physics

- Semiconductor fabrication

- Industrial applications

- XHV quantum physics

- Beam tubes

- Wigglers and undulators

- Free electron lasers (FEL)

- Drift tubes

- Spectrometers

Low Z, Low Nuclear: Atlas titanium-aluminum flanges enable aluminum UHV systems to be used in demanding nuclear applications requiring a low z environment.

- Cyclotrons

- Nuclear reactors

- Medical imaging

Light/Low Weight: With weight-to-volume ratios 1/3 that of stainless vacuum chambers, an aluminum chamber with Ti/Al flanges significantly reduces overall weight:

- Aerospace

- Portable systems

Features & Specifications:

- UHV Rated to 1 x 10-13 Torr

- Bake-out temperatures up to 250°C

- 1/3 the weight of stainless flanges

- Fully compatible with industry standard ConFlat flange interface – CERN’s innovative 20° back-bevel (90° included angle) knife-edge design

- Standard flange sizes: 1.33”-16.5” (DN16-DN500)

- Used in high (HV), ultrahigh (UHV) and extreme high vacuum (XHV) applications

Materials

- Body/weld interface: aluminum 6061-T6

- Sealing knife-edge face: titanium grade 2, (commercially pure titanium optional)

- Rotatable collar/receiver: aluminum 6061-T6, titanium 0ptional

Environmental

- Vacuum leak tested: < 1 x 10-9 cc/sec of He

Thermal

- Peak temperature: 300°C (during weld-up)

- Operational temperature: -200°C to 250°C

Mechanical—Bonded Interface

- Tensile: 15,00psi (103MPa)

- Shear: 10,000psi (69MPa)

Copyright Atlas Technologies | All Rights Reserved