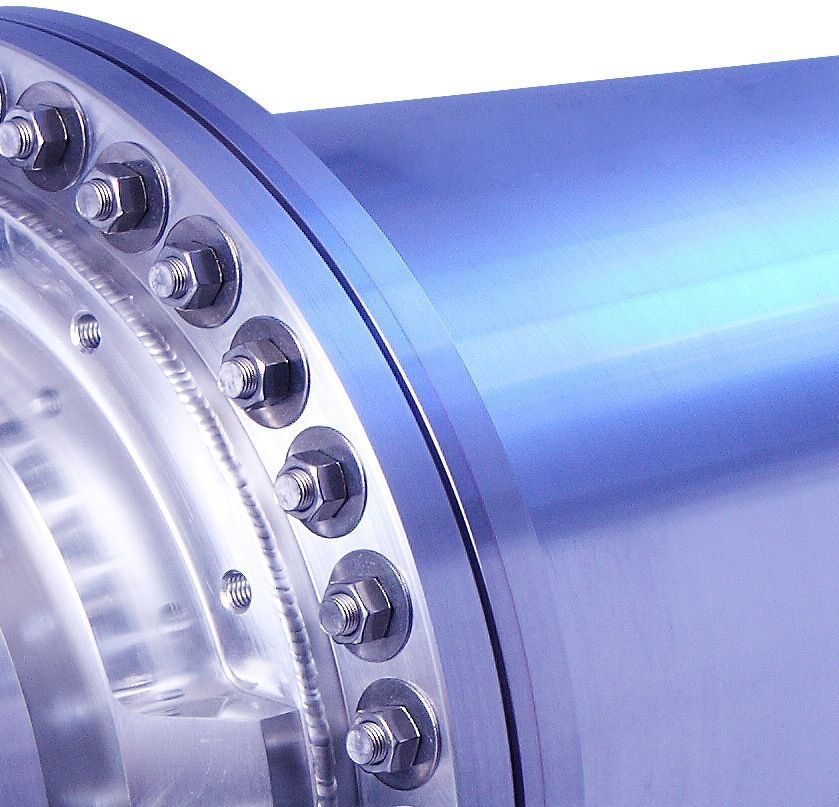

Atlas Wire-Seal Flanges are made from large-area Atlas bonded material. A male and female flange compresses an 0.080 inch diameter OFHC copper wire to effect a seal. A back bevel on the knife-edge improves the seal by making it more tolerant to thermal cycles, as well as enhancing its durability.

These flanges utilize a 316L stainless steel sealing surface to crush a wire gasket and a 6061-T6 aluminum flange body for weld-up to Atlas aluminum chambers. All Wire-Seal Flanges are vacuum tested and guaranteed leak tight to a rate of 1 x 10-9 cc/sec of He prior to shipping.

Applications

- Large vacuum chambers, bell jars and similar systems

- Particle research

- Energy and climate research