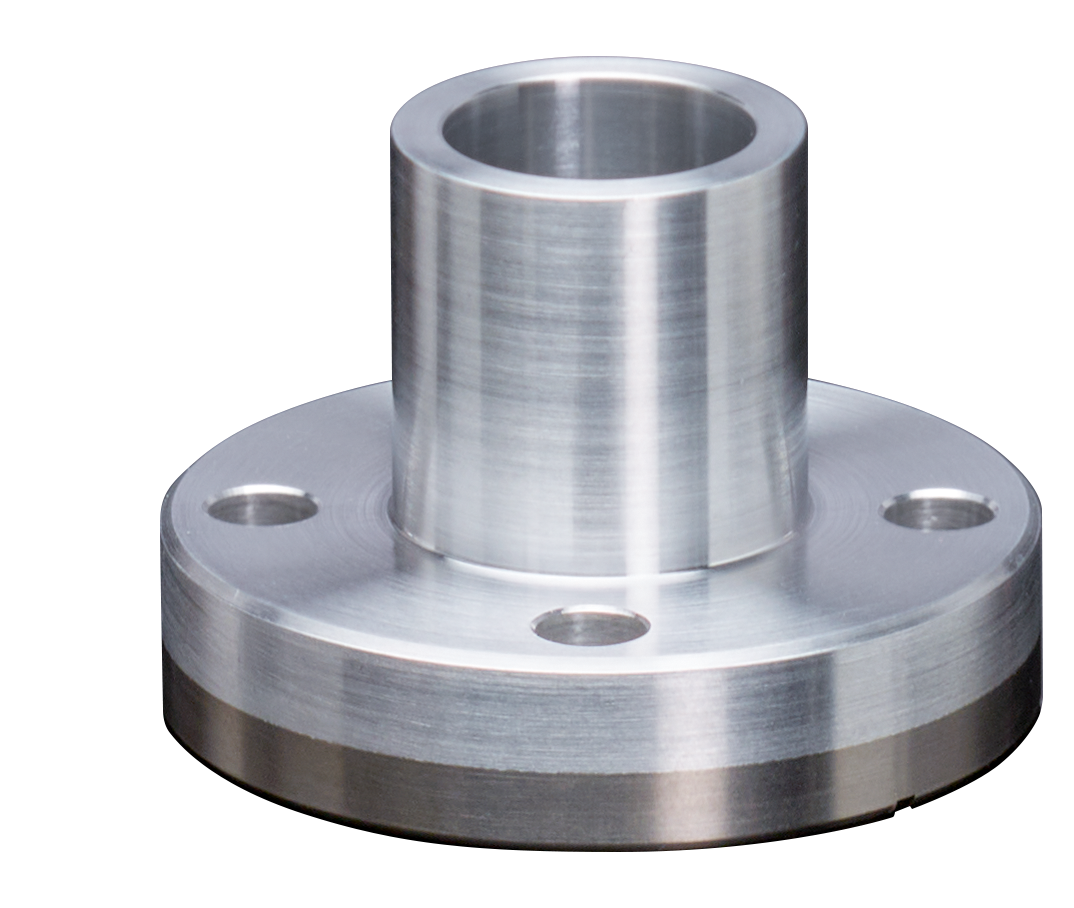

Bimetal Ti/Al CF Flanges

Durable, non-magnetic UHV sealing for aluminum vacuum chambers

Atlas Bimetal Ti/Al CF Flanges feature an aluminum flange body bonded to a rugged titanium face for a completely non-magnetic vacuum system.

Rotation

Bolt Holes

Bore

14.50" (368mm/DN300) weld neck bimetal Ti/Al CF flange

Bimetal flanges and fittings typically ship in 4-5 weeks. Please contact us to check inventory or inquire about expediting your order.

Online orders are available for US and Canada only. Prices will differ in other regions.

Contact your local sales team for more information

Product Specifications

Titanium UHV Sealing for Aluminum Chambers

The Atlas Bimetal Ti/Al CF Flange with aluminum flange body bonded to rugged titanium uses the time-tested reliability of the ConFlat® (CF) knife-edge seal. After welding the CFTA™ flange to an aluminum vacuum chamber, it becomes a completely non-magnetic UHV chamber. This supports applications where high magnetic permeability is detrimental to beam quality or experimental results.

Non-magnetic aluminum vacuum chambers are used for UHV synchrotron, particle physics, and industrial applications where high magnetic permeability is detrimental to beam quality or experimental results. Such applications include non-magnetic beam tubes, wigglers, undulators, free electron lasers (FEL), drift tubes, and spectrometers.

Applications:

- UHV synchrotron

- Particle physics

- Semiconductor fabrication

- Industrial applications

- XHV quantum physics

- Beam tubes

- Wigglers and undulators

- Free electron lasers (FEL)

- Drift tubes

- Spectrometers

Low Z, Low Nuclear: Atlas titanium-aluminum flanges enable aluminum UHV systems to be used in demanding nuclear applications requiring a low z environment.

- Cyclotrons

- Nuclear reactors

- Medical imaging

Light/Low Weight: With weight-to-volume ratios 1/3 that of stainless vacuum chambers, an aluminum chamber with Ti/Al flanges significantly reduces overall weight:

- Aerospace

- Portable systems

Features & Specifications:

- UHV Rated to 1 x 10-13 Torr

- Bake-out temperatures up to 250°C

- 1/3 the weight of stainless flanges

- Fully compatible with industry standard ConFlat flange interface – CERN’s innovative 20° back-bevel (90° included angle) knife-edge design

- Standard flange sizes: 1.33”-16.5” (DN16-DN500)

- Used in high (HV), ultrahigh (UHV) and extreme high vacuum (XHV) applications

Materials

- Body/weld interface: aluminum 6061-T6

- Sealing knife-edge face: titanium grade 2, (commercially pure titanium optional)

- Rotatable collar/receiver: aluminum 6061-T6, titanium 0ptional

Environmental

- Vacuum leak tested: < 1 x 10-9 cc/sec of He

Thermal

- Peak temperature: 300°C (during weld-up)

- Operational temperature: -200°C to 250°C

Mechanical—Bonded Interface

- Tensile: 15,00psi (103MPa)

- Shear: 10,000psi (69MPa)

Copyright Atlas Technologies | All Rights Reserved