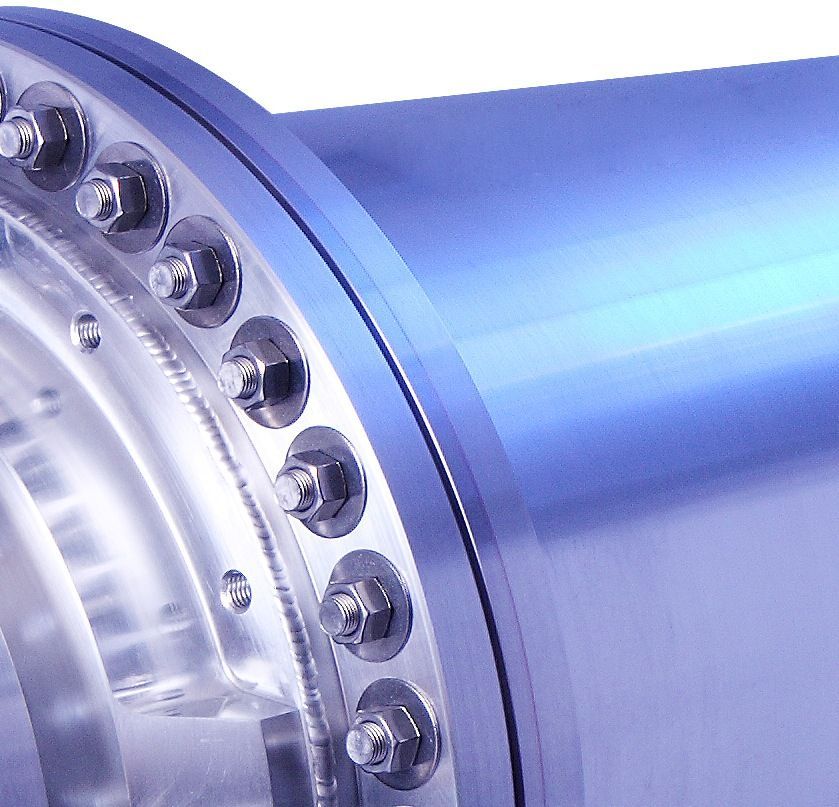

Bimetal Al/SS Wire Seal Flanges

The demountable flange for large UHV sealing surfaces

When size requirements for demountable flanges exceed that of standard Atlas CF Flanges, our bimetallic Wire-Seal Flanges enable sealing of large chambers.

22.13" (562mm) bimetal Al/SS wire seal flange, female, mounts to 18" (457.2mm) tube with Ø17.75" (451mm) bore

Bimetal flanges and fittings typically ship in 4-5 weeks. Please contact us to check inventory or inquire about expediting your order.

Online orders are available for US and Canada only. Prices will differ in other regions.

Contact your local sales team for more information

Product Specifications

Atlas Wire-Seal Flanges are made from large-area Atlas bonded material. A male and female flange compresses an 0.080 inch diameter OFHC copper wire to effect a seal. A back bevel on the knife-edge improves the seal by making it more tolerant to thermal cycles, as well as enhancing its durability.

These flanges utilize a 316L stainless steel sealing surface to crush a wire gasket and a 6061-T6 aluminum flange body for weld-up to Atlas aluminum chambers. All Wire-Seal Flanges are vacuum tested and guaranteed leak tight to a rate of 1 x 10-9 cc/sec of He prior to shipping.

Applications

- Large vacuum chambers, bell jars and similar systems

- Particle research

- Energy and climate research

Features & Specifications

- Demountable flanges for large sealing surfaces

- Back bevel on knife edge improves tolerance for thermal cycles

Materials

- Standard: aluminum 6061 T6 bonded to 316L stainless steel

- Custom options include aluminum 6061 T6 bonded to titanium grade 2 or all-titanium grade 5

Features

- Aluminum to stainless bimetallic construction

- 1/3 the weight of stainless steel flanges

- UHV/XHV rated to 1 x 10-13 Torr.

- 100% compatible with third-party stainless wire-seal hardware

Environmental

- Vacuum leak tested to < 1 x 10-9 cc/sec of He

Thermal

- Peak temperature (during weld-up) 300°C

- Operational temperature from -200°C to 250°C

Mechanical - Bonded Interface

- Tensile: 15,00psi (103MPa)

- Shear: 10,000psi (69MPa)

Copyright Atlas Technologies | All Rights Reserved