-

EXPERTS IN BONDED DISSIMILAR METALS & PERFORMANCE VACUUM SOLUTIONS

DESIGN DEVELOP MANUFACTURE SUPPORT

Button -

EXPERTS IN BONDED DISSIMILAR METALS & PERFORMANCE VACUUM SOLUTIONS

DESIGN DEVELOP MANUFACTURE SUPPORT

Button -

EXPERTS IN BONDED DISSIMILAR METALS & PERFORMANCE VACUUM SOLUTIONS

DESIGN DEVELOP MANUFACTURE SUPPORT

Button

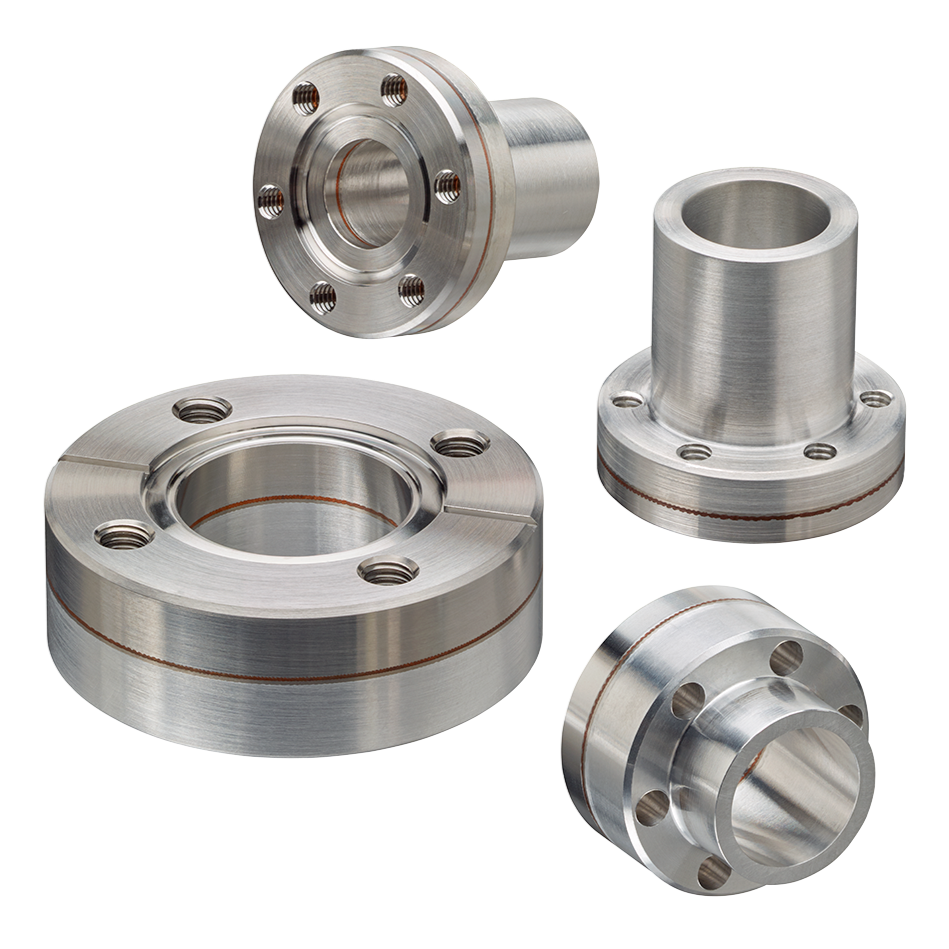

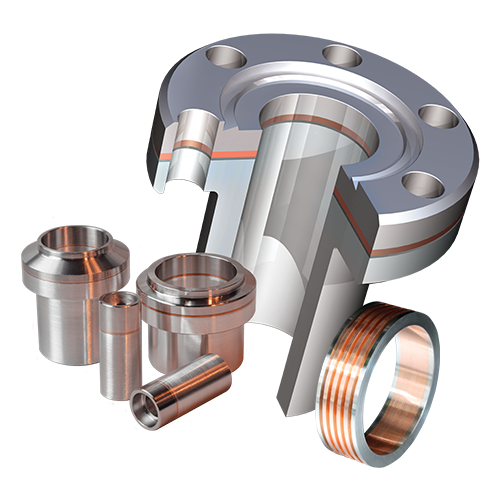

DISSIMILAR METAL PRODUCTS

Atlas dissimilar metal bonds are mechanically robust, totally hermetic, and remain ductile in pyrolytic or cryogenic temperatures. With solid-state explosion bonding, diffusion bonding, and roll bonding, a huge variety of metals can be joined and can then be further machined and welded to adjacent metals.

The bonds are so strong and reliable, they are used in Ultra High Vacuum (UHV) and Extreme High Vacuum (XHV) applications for the semiconductor, chemical processing, cryogenics, aerospace, and particle physics industries where even infinitesimal porosity or leakage is intolerable.

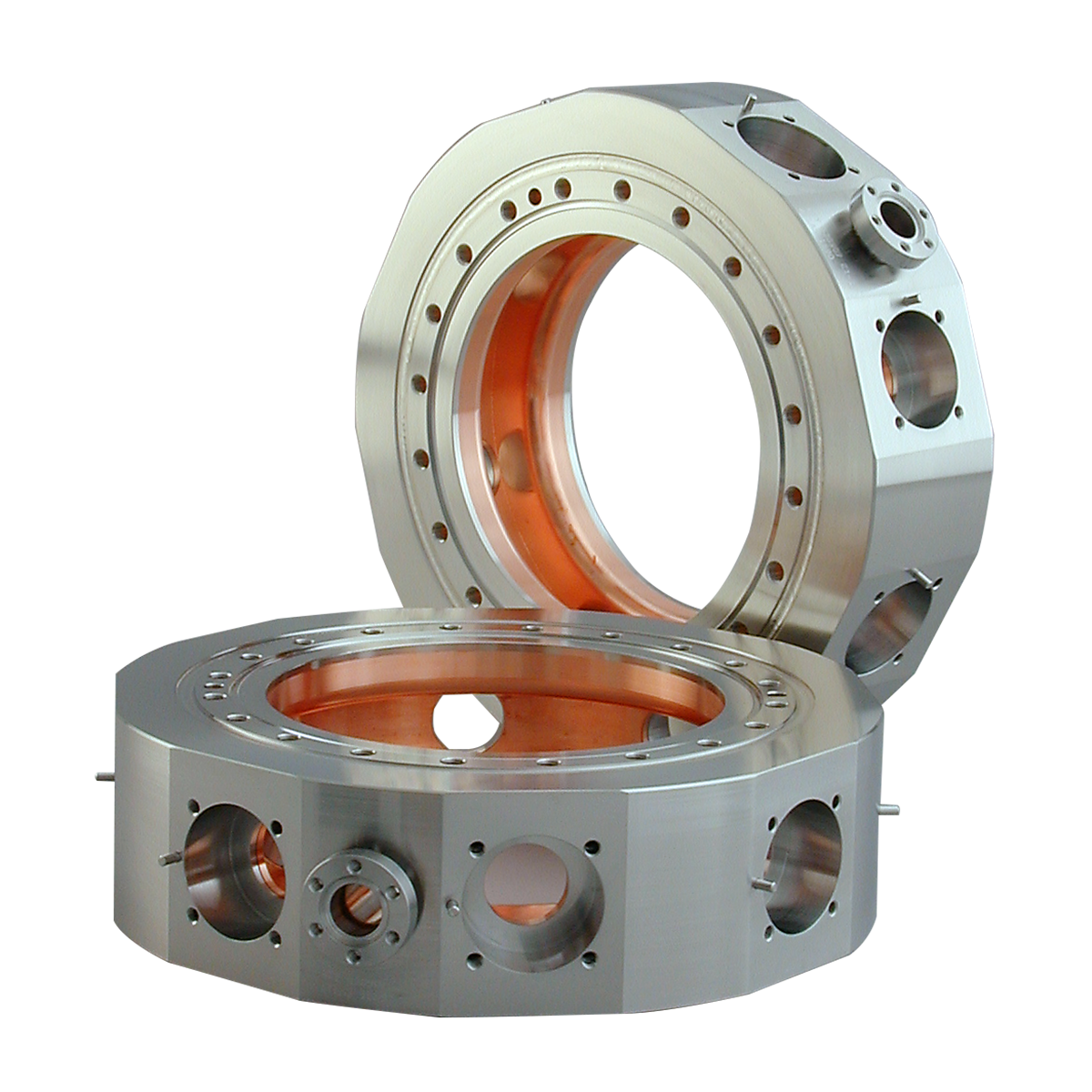

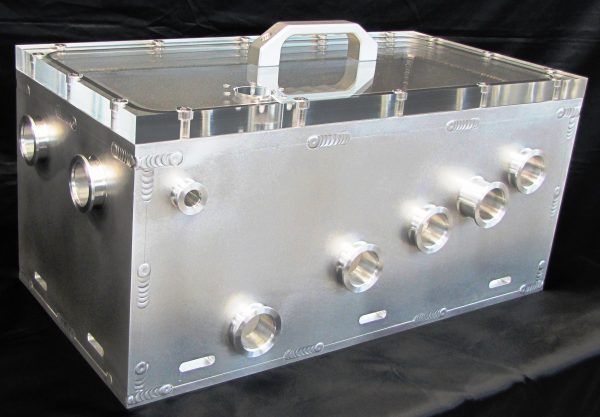

CUSTOM VACUUM CHAMBERS

We thoroughly understand the vacuum and manufacturing subtleties in making aluminum, titanium and copper chambers. We are eager to assist you in applying this knowledge toward your specific application. Our passion for materials will help you obtain the performance you are looking for.

Because of our dissimilar metal bonding experience, we approach vacuum material usage with an open mind. We are able to circumvent many welding or joining issues and can apply a wide variety of materials and material conditions precisely where they are needed.

DESIGN • DEVELOP • MANUFACTURE • SUPPORT

From our first custom aluminum vacuum chamber, to our recent niobium to stainless steel fittings for satellite delivery rockets, to our standard bimetal and titanium flanges and fittings, Atlas Technologies has been the solution of choice for mission critical projects around the world. Whether you have a rough sketch, a full-fledged design, or just need a handful of our US-manufactured bimetal products, we can help.

WHAT OUR CUSTOMERS SAY

-

We have decided to make an aluminum lid for the chamber you fabricated for us last winter, as well as a lid for one of our smaller chambers. We are very pleased with the quality of your chamber and would like to improve the vacuum for this entire system.

JUSTIN GRIFFITH - UNIVERSITY OF COLORADO, PHYSICS -

The cube with Ti windows is connected to the beam line at CERN-ISOLDE facility and ready for radioactive-ion beam. The foils are performing very well, they seem to be perfectly light tight, we do not see any noise due to optical photons in the windowless Si(Li) detector that is located in the vacuum chamber.

MARTIN VENHART - CERN -

Damn those Atlas things are good! We're off scale in the chamber with your multiple TSP's. Might be able to say that we're in 13 scale vacuum......very nice! You guys should go market the hell out of these... Congrats!

MIKE ACKERET - TRANSFER ENGINEERING -

The tailpiece with Atlas Al window worked very well. It held vacuum and performed as we had hoped. We were able to get some very good low noise scattering data in just a few minutes using the high intensity of the NOMAD beam line. We're just now analyzing the data.

DR. KENNETH F. KELTON - DIRECTOR, & ARTHUR HOLLY COMPTON - PROFESSOR OF PHYSICS, INSTITUTE FOR MATERIALS SCIENCE & ENGINEERING -

We have been working with Atlas for many years using their Atlas CF flanges and explosion bonding capability for assemblies such as beryllium windows. When we had a need for a dipole magnet vacuum chamber, Atlas competed with vacuum equipment manufacturers worldwide and won the bid, beating out stainless steel vendors in Europe and Russia by a large margin. This is a large chamber ~2.9 m long with two 50 mrad acceptance aperture IR beamlines tangential to the synchrotron electron beam orbit. All flanges including e-beam orbit, synchrotron radiation ports and pumping ports were fabricated from Atlas CF flanges. In addition to the demanding geometrical constraints of the dipole magnet the chamber was required to absorb all excess synchrotron radiation not entering the beamlines and resist any deformation due to forces incurred under vacuum. Atlas presented a preliminary design for approval before fabrication and conducted a complete FEA analysis of the chamber studying both the thermal loading and the vacuum deflection. Atlas fabricated the chamber in two halves with each half having a water cooling surface machined into the chamber. The two halves were welded together and final machining brought the chamber overall thickness tolerance and chamber radius of curvature tolerance to less than 1mm. The chamber is presently installed in the CAMD synchrotron in bending magnet 2 and attains a base pressure less than 5 x10-10 Torr without bakeout.

KEVIN MORRIS, CENTER FOR ADVANCED MICROSTRUCTURES & DEVICES -

The spectrometer was installed in February, and commissioned in March and it was very successful! The resolution was great. Thank you again for doing a great job with the spectrometer, it was very appreciated!

MICHAEL HOLMES & BILL SCHLOTTER, SLAC NATIONAL ACCELERATOR LABORATORY -

During my tenure at Ovonic ECD (United Solar) I was very pleased with the service and quality we received from Atlas Technologies. Before working with Atlas all of our thin film photovoltaic production line was manufactured out of stainless steel. Atlas assisted us in converting the drive and transition chambers to aluminum; this created a substantial (50 to 60%) cost savings. By using the standard weld-on bimetallic Atlas AT- CF flanges we were able to eliminate O-rings and reduce contamination. The quality of the chambers and equipment we have received from them has been exceptional. Furthermore when we commission their chambers it has become worry-free for our installation crews. We maintain a very aggressive production schedule and they have always been accurate, up-front and on time with their delivery commitments. They also price themselves aggressively. I strongly recommend Atlas Technologies for future work.

GEORGE UZONI - FORMERLY, DESIGN SUPERVISOR, ENERGY CONVERSION DEVICES -

This addition (Atlas manufactured aluminum Loadlock Chamber) significantly improved our processing time. The Atlas chamber was delivered on time and is of very high quality workmanship, and is performing flawlessly.

DR. CRAIG OUTTEN - RESEARCH DEVELOPMENT SCIENTIST, DENTON -

The part came into today! I cannot believe that you guys were able to turn around a custom part that quick. It looks perfect! Thank you so much for helping me work through this part and getting an awesome end result. Two thumbs way up!

JAMES M. SOMERS - MECHANICAL ENGINEER, ATK MILITARY SYSTEMS -

Atlas was terrific to work with on our recent order of vacuum chambers. Communication from the production supervisor was proactive and ongoing throughout fabrication, the quality of work was outstanding, and delivery time was faster than expected. Couldn't be more satisfied!

DEREK YEGIAN - ENGINEER, EUV TECH -

All the chambers have performed very well, met our specifications, and they were beautiful!

SERGEI NAGAITSEV - DEPUTY DIRECTOR, FERMILAB -

Atlas Technologies is one little diamond in a vast wasteland of good intentions. Their bimetal and aluminum products and problem solving, (a very unique skill set) are so...valuable.

JOHN SKARITKA - MECHANICAL ENGINEER, BROOKHAVEN NATIONAL LABS -

Atlas Technologies has a very unique skill-set that is very special. They are the only ones in the country (the world) who really know aluminum and they have the ability in bimetal that enables them to solve so many UHV & XHV problems and do so much. They are also very good to work with., really great people!

JOHN SKARITKA - MECHANICAL ENGINEER, BROOKHAVEN NATIONAL LABS

WHY ATLAS?

Experienced Problem Solvers

For over 20 years, Atlas Technologies’ Enhanced Vacuum Technology Products and Services have helped lead the aluminum ultra-high vacuum revolution. We love to develop new products that better serve you, our customers.

Precision Products, High-Performance Materials

Our bimetallic technology often allows us to solve some of your most difficult challenges and help you think about your project with more options than just stainless steel.

Expertly-Crafted Solutions Made in the USA

Our inventions give innovators the tools to advance energy, space, medicine, physics, quantum computing, and commodity preservation. All crafted in the USA.

Satisfied Customers

We’re proud to contribute to the success of thousands of leading edge customers from some of the most prestigious institutions around the world.

leading-edge Products

ATLAS NEWS AND ARTICLES

Copyright Atlas Technologies | All Rights Reserved